News

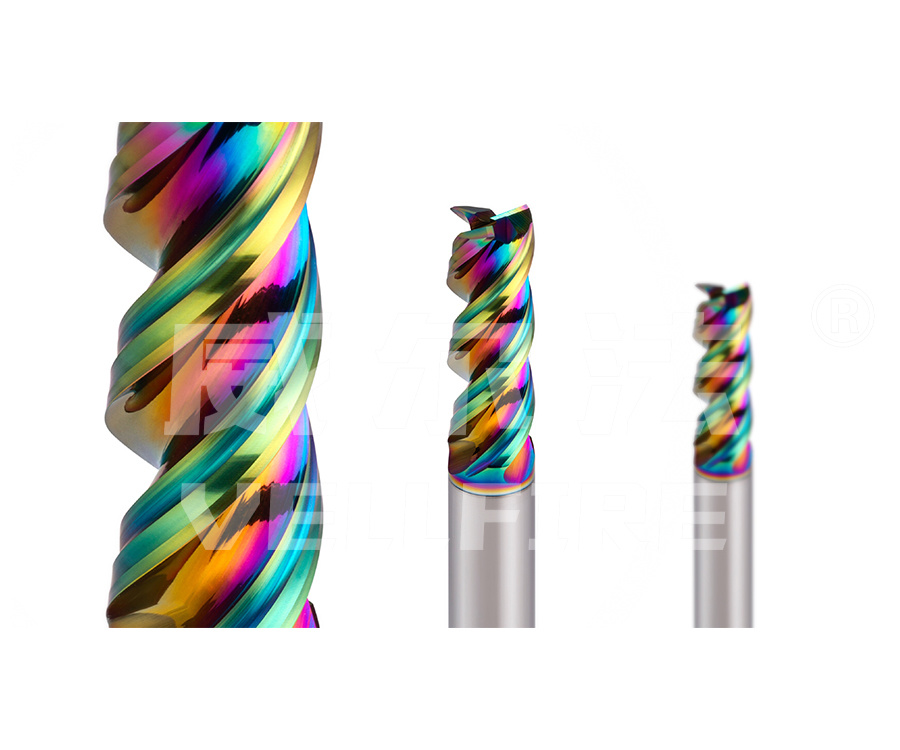

Fabrication method of tube sheet bit

Release time:

2022/01/27

Tube sheet bitThe difficulty of processing is an important factor restricting the manufacturing cycle and cost of heat exchanger. Ordinary drill bits not only have low processing efficiency, but also are difficult to solve the problems of shoulder drop and shoulder drop in deep hole processing. The strength and heat dissipation performance of the tool tip cannot meet the processing requirements of tube plate drill bits under this special situation. Then, let's learn about the manufacturing method of tube plate drill bits together!

The ordinary drill bit has only one tooth gap, the bottom arc is small, and the sharp inflection point is connected with the front face of the groove. According to the relevant knowledge of metal cutting tools, in the processing of high cutting speed, in order to make the shoulder at the back gap fall smoothly, the back gap needs enough shoulder storage space. For a drill bit with a small arc at the bottom of the tooth gap, in order to improve the shoulder accommodation space at the tooth gap, a large overshoot cannot be generally used. If the arc r at the bottom of the backlash is small, the overshoot is large, the strength of the chisel edge is too low, the chisel edge is easy to defect, the centering ability of the tool is lost in advance, and the life of the tool and the number of grinding are reduced.

Stress concentration occurs at the inflection point of the tube sheet bit gap and the forward inclined surface of the groove, which causes excessive wear and edge chipping during processing, and also affects the curling shape of the tire shoulder. When processing materials with high ductility, the shoulder is not easy to break, and the long shoulder is wound with the tool, which affects the shoulder of the tool. If you don't clean the long iron shoulder on the tool immediately, the tool will not be able to break side by side smoothly.

The tip of an ordinary drill is chamfered and the flank is flat. When the feed is large in deep hole processing, especially when the strength is insufficient and the heat dissipation area is not large enough, so the cutting heat is concentrated on the tip and cannot be quickly transferred to the coolant. Therefore, the tool tip is prone to shoulder acid, and continuous use is the occurrence of blade leakage, making the tool invalid.

Utility model content

The tube sheet drill bit provides a tube sheet hole processing drill bit with high cutting edge strength, large space into the shoulder, and can adapt to a variety of harsh processing environments.

The utility model claims:Tube sheet bitThe tool body is provided with a main cutting edge, a nose chamfering flank, a main flank, a secondary flank, a groove rake face, a main edge belt and a flank, which are arranged on the end face of the tool body and are divided into a groove rake face and a main flank face on both sides of the main cutting edge, and are arranged at a position closer to the groove rake face side than the outer edge of the main flank face, the edge of the main flank face close to the center of the end face of the tool main body includes the first backlash close to the center side of the end face, and the second backlash of the first backlash and the groove rake face at both ends.

The beneficial effects of the tube sheet bit are:

1. The utility model provides a drill bit, which has a large arc at the bottom of the gap, takes into account the strength of the chisel edge and the shoulder space of the gap, and enhances the front end strength and centering ability of the drill bit.

2. Increase the second backlash to reduce the stress concentration at the joint between the backlash and the forward inclined surface of the groove. At the same time, change the winding mode of the shoulder to improve the shoulder cutting performance of the tool, so that the shoulder does not wind with the tool and the shoulder of the tool is smooth.

3. Optimize the structure of the rear edge surface of the tool tip chamfer, change the traditional plane rear angle form to the cylindrical rear angle form, increase the surface area of the rear edge surface of the tool tip chamfer, which increases the heat dissipation area and improves the heat dissipation performance of the tool. In addition, the main deflection angle of the tip chamfer is relative to the previous 45. The utility model has been optimized to reach 35. The cutting thickness on the tip can be reduced, and the processing at high feed speed not only greatly reduces the chance of the tip chamfer breaking, but also improves the strength of the tip.

Tube sheet bitInvolved in the field of tube plate hole processing technology, high cutting edge strength, large chip holding space, can adapt to a variety of harsh processing environment. The technology of the utility model includes the main cutting edge, the rear face of the front face of the drill bit, the main rear face, the first side gap, the second side gap, the groove front face, the main edge belt, and the tool body with the chip removal groove The tool shank is integrated with the tool body.

The above introduction is the production method of tube plate drill, if you need to know more, you can contact us at any time!

keywords

Previous Page

Latest News

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved