Products

UX series economical general purpose end mill

Below HRC55 °

Product Characteristics:It is suitable for side milling and end milling of general steel parts, stainless steel, titanium alloy, kovar alloy and other metal materials.

Product Details

α1 ≠ α2 ≠ α3 ≠ α4, unequal blade designall unequal design The cutting vibration frequency of each edge is different when cutting with high efficiency High efficiency cutting without vibration

|

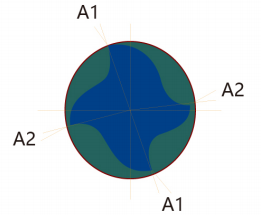

A1 ≠ A2 Variable groove rake angle designThe variable groove rake angle is matched with a large cutting amount to achieve high-efficiency cutting.

|

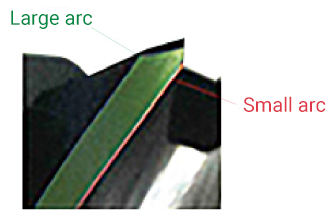

Design of small arc and large arc rear angleThe small arc rear angle improves the smoothness of the machined surface while improving the machining life. The large arc rear angle provides perfect support for high-efficiency rough machining of high-temperature alloys.

|

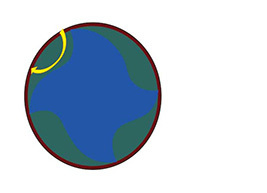

Special trough designSpecial groove design for smooth discharge of iron filings

|

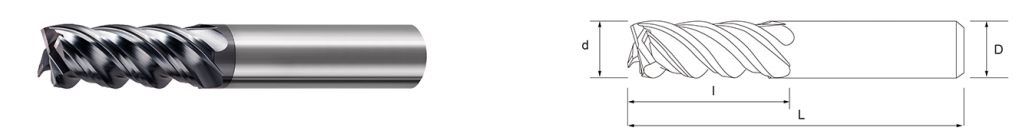

Product Model

| Blade diameter (d) | Blade length (I) | Shank diameter (D) | Total length (I) | Blade number (F) |

| 1 | 3 | 4 | 50 | 4 |

| 1.5 | 3.5 | 4 | 50 | 4 |

| 2 | 5 | 4 | 50 | 4 |

| 2.5 | 6 | 4 | 50 | 4 |

| 3 | 8 | 4 | 50 | 4 |

| 3.5 | 10 | 4 | 50 | 4 |

| 4 | 10 | 4 | 50 | 4 |

| 4 | 12 | 4 | 75 | 4 |

| 4 | 16 | 4 | 100 | 4 |

| 4R0.2 | 10 | 4 | 50 | 4 |

| 4R0.5 | 10 | 4 | 50 | 4 |

| 4R1 | 10 | 4 | 50 | 4 |

| 5 | 13 | 6 | 50 | 4 |

| 5 | 20 | 5 | 75 | 4 |

| 6 | 15 | 6 | 50 | 4 |

| 6 | 18 | 6 | 50 | 4 |

| 6 | 24 | 6 | 75 | 4 |

| 6 | 30 | 6 | 100 | 4 |

| 6R0.5 | 15 | 6 | 50 | 4 |

| 6R1 | 15 | 6 | 50 | 4 |

| 8 | 20 | 8 | 60 | 4 |

| 8 | 24 | 8 | 60 | 4 |

| 8 | 30 | 8 | 75 | 4 |

| 8 | 35 | 8 | 100 | 4 |

| 8R0.5 | 20 | 8 | 60 | 4 |

| 8R1 | 20 | 8 | 60 | 4 |

| 10 | 25 | 10 | 75 | 4 |

| 10 | 30 | 10 | 75 | 4 |

| 10 | 40 | 10 | 100 | 4 |

| 10R0.5 | 25 | 10 | 75 | 4 |

| 10R1 | 25 | 10 | 75 | 4 |

| 12 | 30 | 12 | 75 | 4 |

| 12 | 36 | 12 | 75 | 4 |

| 12 | 45 | 12 | 100 | 4 |

| 12R0.5 | 30 | 12 | 75 | 4 |

| 12R1 | 30 | 12 | 75 | 4 |

| 14 | 40 | 14 | 100 | 4 |

| 16 | 45 | 16 | 100 | 4 |

| 20 | 45 | 20 | 100 | 4 |

Support non-standard specification customization

Recommended reference cutting parameters

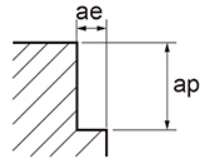

Recommended cutting conditions side cuttingAccording to the four elements of processing conditions: Machine tool rigidity, fixture firmness, tool holding force, Under the condition of excellent chip removal, choose reasonable processing parameters cutting parameters finishing, Cutting speed can be appropriately reduced. |

|

| Processing material | Carbon steel, alloy steel, mild steel | Pre-hardened die steel, alloy steel, alloy tool steel | Ferritic stainless steel, austenitic stainless steel, titanium alloy, Kovar alloy | |||||||||

|

A3, 45 steel, 40Mn, 40Cr, |

NAK80、718H、SDK、P20、 30CrMnSiA, Cr12, etc. |

201、304、430、316L、 TC4、TC6、4J29 |

||||||||||

| Outer diameter D (mm) | Number of revolutions S (min) | Feed speed F (mm/min) | Cutting depth ap (mm) | Cutting width AE (mm) | Number of revolutions S (min) | Feed speed F (mm/min) | Cutting depth ap (mm) | Cutting width AE (mm) | Number of revolutions S (min) | Feed speed F (mm/min) | Cutting depth ap (mm) | Cutting width AE (mm) |

| 3 | 8000 | 1500 | 5 | 0.3 | 6000 | 1000 | 5 | 0.2 | 6000 | 800 | 5 | 0.2 |

| 4 | 8000 | 1500 | 8 | 0.4 | 6000 | 1000 | 8 | 0.2 | 5000 | 800 | 8 | 0.2 |

| 5 | 6000 | 1500 | 10 | 0.5 | 5000 | 1000 | 10 | 0.3 | 4500 | 800 | 10 | 0.3 |

| 6 | 6000 | 1500 | 10 | 0.6 | 5000 | 1000 | 10 | 0.3 | 4500 | 800 | 10 | 0.3 |

| 8 | 4000 | 1500 | 15 | 0.8 | 5000 | 1200 | 15 | 0.4 | 3300 | 1000 | 15 | 0.4 |

| 10 | 3500 | 1500 | 20 | 1 | 3000 | 1200 | 20 | 0.5 | 3000 | 1000 | 20 | 0.5 |

| 12 | 2700 | 1200 | 25 | 1.2 | 2500 | 1200 | 25 | 0.6 | 2500 | 1000 | 25 | 0.6 |

| 16 | 2000 | 1200 | 30 | 1.6 | 2000 | 800 | 30 | 0.8 | 1700 | 800 | 30 | 0.8 |

| 20 | 2000 | 1200 | 40 | 2 | 2000 | 800 | 40 | 1 | 1700 | 800 | 40 | 1 |

| Depth of cut datum |  |

|||||||||||

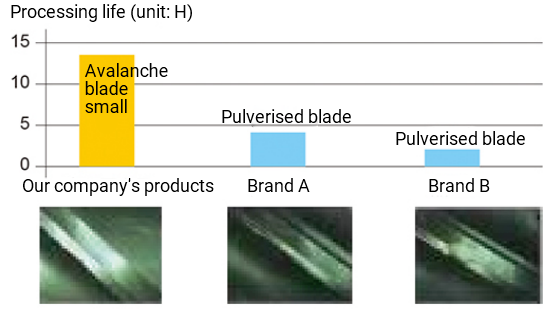

Processing Case 1 (Coarse and Fine Integration)

| Using tools | UX-D10*25*75*4T |

| Processing materials | SUS304 |

| Processing mode | Dynamic milling |

| Cutting speed | 110m/min(3500min-1) |

| Feed speed | 500mm/min(0.036mm/Fz) |

| Cutting depth | Ap=15mm Ae=2mm |

| Cooling mode | Emulsion |

| Use of machine tools | Vertical machining center (HSK50A) |

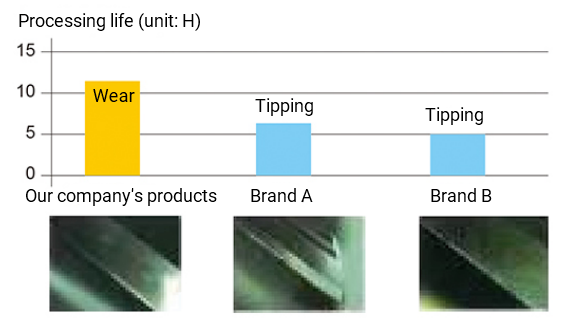

Machining Case 2 (Fine Milling)

| Using tools | UX-D10*25*75*4T |

| Processing materials | SUS304 |

| Processing mode | fine milling |

| Cutting speed | 110 m/min(3500min-1) |

| Feed speed | 800mm/min(0.057mm/Fz) |

| Cutting depth | Ap=15mm Ae=0.15mm |

| Cooling mode | Emulsion |

| Use of machine tools | Vertical machining center (HSK50A) |

Keywords: UX series economical general purpose end mill

Online Message

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

E-mail: amy@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved