Products

NX series stainless steel (steel) high efficiency heavy cutting milling cutter

Below HRC55 °

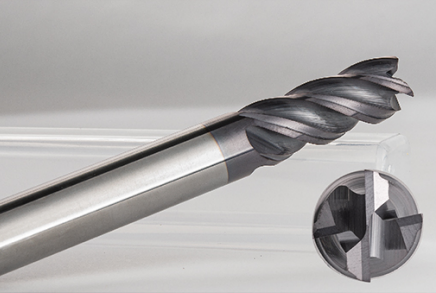

Product Characteristics:It is suitable for large cutting, high feed side milling and grooving of general steel parts, stainless steel, titaniumalloy, superalloy and kovar alloy.

Product Details

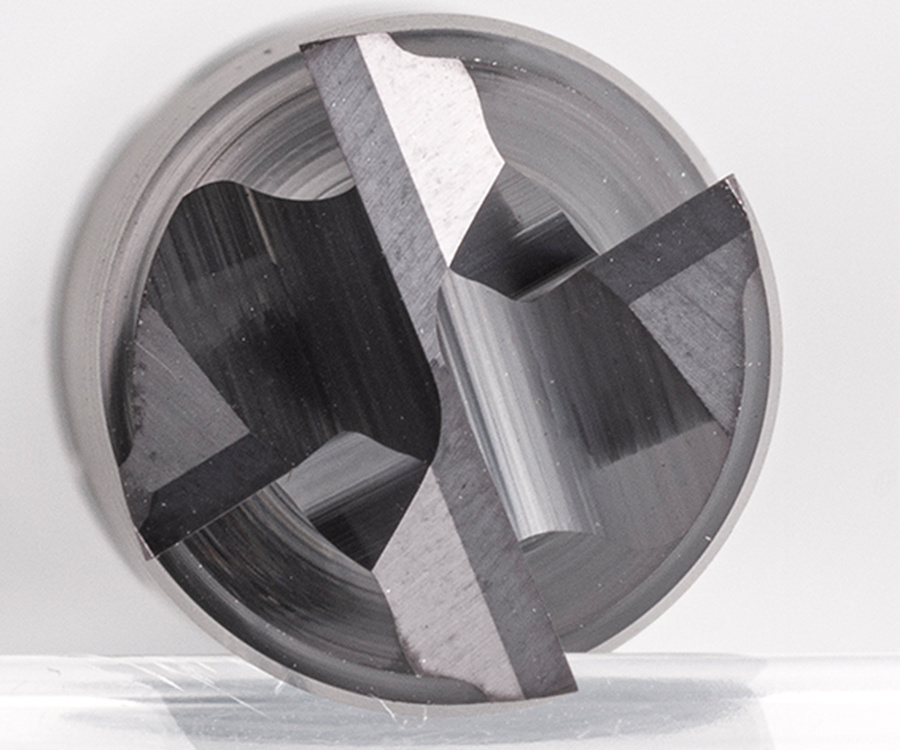

α ≠ β, Unequal edge designLarge unequal design, in the suppression of tool vibration; high efficiency cutting at the same time to improve the finish of the processing surface.

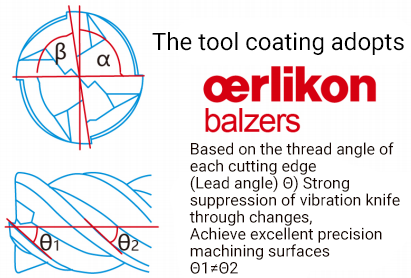

θ1 #θ2 Unequal lead designThe lead angle of each cutting edge changes to suppress knife vibration; to achieve excellent finishing surface.

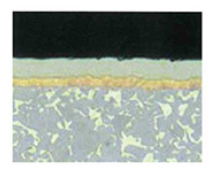

The latest research and development of multi-layer coating designThe newly developed AICrNJI-based multilayer coating, wear-resistant layer and heat-resistant layer of fine-grained cemented carbide substrate have good wear resistance, thermal stability and smoothness, and are suitable for high-temperature alloys, stainless steel and other difficult-to-process materials.

|

Cutting edge smooth treatmentSpecially designed for high-temperature alloy cutting edge smooth treatment, greatly reducing the friction between the milling cutter and iron filings, improve processing efficiency and life.

|

Product Model

| Blade diameter (d) | Blade length (I) | Shank diameter (D) | Total length (1) | Blade number (F) |

| 1 | 3 | 4 | 50 | 4 |

| 1.5 | 3.5 | 4 | 50 | 4 |

| 2 | 5 | 4 | 50 | 4 |

| 2.5 | 6 | 4 | 50 | 4 |

| 3 | 8 | 4 | 50 | 4 |

| 3 | 9 | 6 | 50 | 4 |

| 3.5 | 10 | 4 | 50 | 4 |

| 4 | 10 | 4 | 50 | 4 |

| 4 | 12 | 4 | 75 | 4 |

| 4 | 16 | 4 | 100 | 4 |

| D4R0.1 | 10 | 4 | 50 | 4 |

| D4R0.2 | 10 | 4 | 50 | 4 |

| 4R0.5 | 10 | 4 | 50 | 4 |

| 4R1 | 10 | 4 | 50 | 4 |

| 4 | 11 | 6 | 50 | 4 |

| 5 | 13 | 6 | 50 | 4 |

| 5 | 20 | 5 | 75 | 4 |

| 5 | 25 | 5 | 100 | 4 |

| 5R0.2 | 13 | 6 | 50 | 4 |

| 6 | 15 | 6 | 50 | 4 |

| 6 | 18 | 6 | 50 | 4 |

| 6 | 24 | 6 | 75 | 4 |

| 6 | 30 | 6 | 100 | 4 |

| 6R0.2 | 15 | 6 | 50 | 4 |

| 6R0.5 | 15 | 6 | 50 | 4 |

| 6R1 | 15 | 6 | 50 | 4 |

| 8 | 20 | 8 | 60 | 4 |

| 8 | 24 | 8 | 60 | 4 |

| 8 | 30 | 8 | 75 | 4 |

| 8 | 35 | 8 | 100 | 4 |

| 8R0.5 | 20 | 8 | 60 | 4 |

| 8R1 | 20 | 8 | 60 | 4 |

| 10 | 25 | 10 | 75 | 4 |

| 10 | 30 | 10 | 75 | 4 |

| 10 | 40 | 10 | 100 | 4 |

| 10R0.5 | 25 | 10 | 75 | 4 |

| 10R1 | 25 | 10 | 75 | 4 |

| 12 | 30 | 12 | 75 | 4 |

| 12 | 36 | 12 | 75 | 4 |

| 12 | 45 | 12 | 100 | 4 |

| 12R0.5 | 30 | 12 | 75 | 4 |

| 12R1 | 30 | 12 | 75 | 4 |

| 14 | 40 | 14 | 100 | 4 |

| 16 | 45 | 16 | 100 | 4 |

| 20 | 45 | 20 | 100 | 4 |

Support non-standard specification customization

Recommended reference cutting parameters

Recommended cutting conditions side cuttingAccording to the four elements of processing conditions: Machine tool rigidity, fixture firmness, tool holding force, Under the condition of excellent chip removal, choose reasonable processing parameters cutting parameters finishing, Cutting speed can be appropriately reduced |

|

| Processing material | Carbon steel, alloy steel, mild steel | Pre-hardened die steel, alloy steel, alloy tool steel | Ferritic stainless steel, austenitic stainless steel, titanium alloy, Kovar alloy | |||||||||

| A3, 45 steel, 40Mn, 40Cr, 40CrMo, 20CrMnTi, etc |

NAK80、718H、SDK、P20、 30CrMnSiA, Cr12, etc. |

201、304、430、316L、 TC4、TC6、4J29 |

||||||||||

| Outer diameter D (mm) | Number of revolutions S (min) | Feed speed F (mm/min) | Cutting depth ap (mm) | Cutting width AE (mm) | Number of revolutions S (min) | Feed speed F (mm/min) | Cutting depth ap (mm) | Cutting width AE (mm) | Number of revolutions S (min) | Feed speed F (mm/min) | Cutting depth ap (mm) | Cutting width AE (mm) |

| 1 | 8000 | 1500 | 2 | 0.1 | 8000 | 1000 | 2 | 0.1 | 8000 | 800 | 2 | 0.05 |

| 2 | 8000 | 1500 | 4 | 0.1 | 8000 | 1000 | 4 | 0.1 | 8000 | 800 | 4 | 0.1 |

| 3 | 8000 | 1500 | 5 | 0.3 | 6000 | 1000 | 5 | 0.2 | 6000 | 800 | 5 | 0.2 |

| 4 | 8000 | 1500 | 8 | 0.4 | 6000 | 1000 | 8 | 0.2 | 5000 | 800 | 8 | 0.2 |

| 5 | 6000 | 1500 | 10 | 1.0 | 5000 | 1000 | 10 | 0.3 | 4500 | 1200 | 10 | 0.3 |

| 6 | 6000 | 1500 | 10 | 1.0 | 5000 | 1000 | 10 | 0.3 | 4500 | 1200 | 10 | 0.3 |

| 8 | 4000 | 1500 | 15 | 1.5 | 5000 | 1200 | 15 | 0.4 | 3300 | 2500 | 15 | 0.4 |

| 10 | 3500 | 1500 | 20 | 2.0 | 3000 | 1200 | 20 | 0.5 | 3000 | 2500 | 20 | 0.5 |

| 12 | 3000 | 1200 | 25 | 2.0 | 2500 | 1200 | 25 | 0.6 | 2800 | 2500 | 25 | 0.6 |

| 16 | 2000 | 1200 | 30 | 3.0 | 2000 | 800 | 30 | 0.8 | 1700 | 1000 | 30 | 0.8 |

| 20 | 2000 | 1200 | 40 | 4.0 | 2000 | 800 | 40 | 1 | 1700 | 800 | 40 | 1 |

| Depth of cut datum |  |

|||||||||||

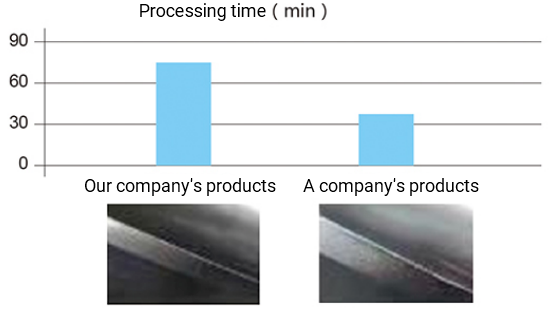

Processing case one (side edge rough machining) steel

| Using tools | NX-D12*30*75*4T |

| Processing materials | 42CrMo(HB180-220) |

| Processing mode | Side milling |

| Cutting speed | 128m/min(3400min-1) |

| Feed speed | 885mm/min(0.065mm/Fz) |

| Cutting depth | Ap=18mm Ae=2.4mm |

| Cooling mode | Water-soluble cutting fluid |

| Use of machine tools | Vertical machining center (BT50) |

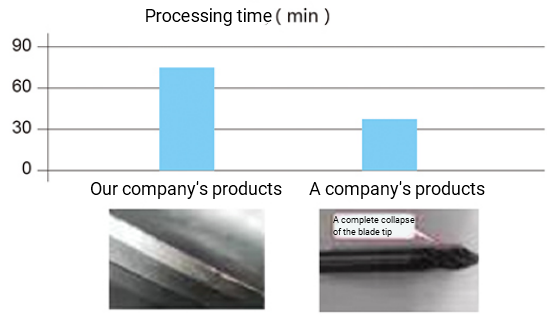

Processing case two (side edge roughing) stainless steel

| Using tools | NX-D12*30*75*4T |

| Processing materials | SUS304 |

| Processing mode | Side milling |

| Cutting speed | 110m/min(2915min-1) |

| Feed speed | 636mm/min(0.0545mm/Fz) |

| Cutting depth | Ap=18mm Ae=2.4mm |

| Cooling mode | Water-soluble cutting fluid |

| Use of machine tools | Vertical machining center (BT50) |

Keywords: NX series stainless steel (steel) high efficiency heavy cutting milling cutter

Online Message

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved