News

U groove milling cutter manufacturers talk about the following factors of tool wear

Release time:

2022/03/25

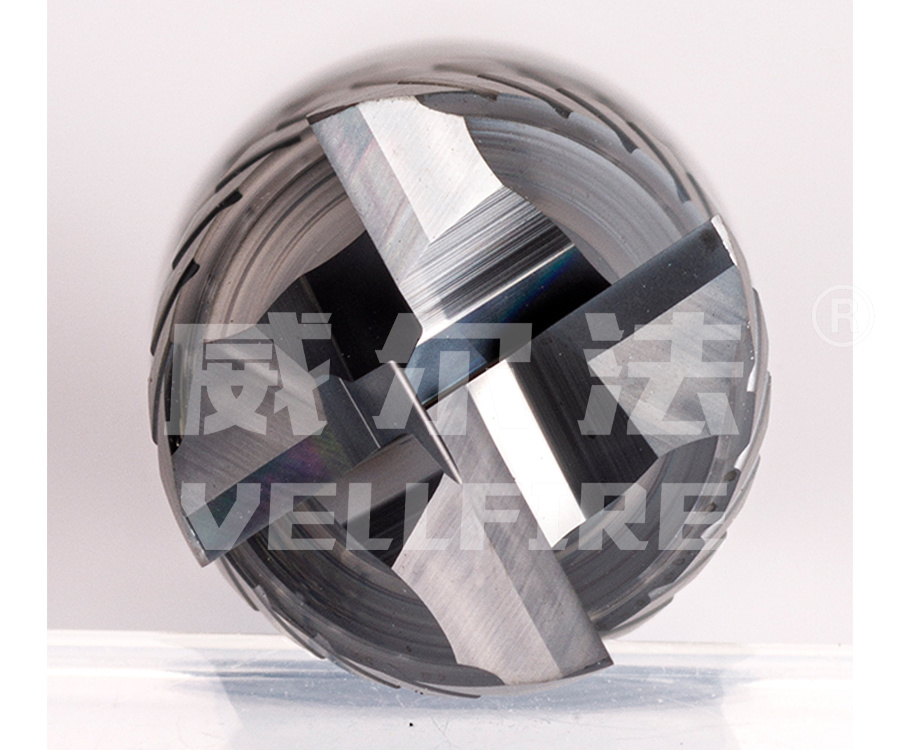

U groove milling cutter manufacturers talk about the following factors of tool wear

Do you know all the factors that affect tool wear? The following manufacturers will answer relevant knowledge for you and help you understand the key points of tool wear.

1. non-standard tool manufacturer indicates that the material of the tool is one

1, chemical wear: at certain temperatures, the tool material and some of the surrounding medium chemical reaction, in the tool surface to form a layer of low hardness of the compound, is the chip or workpiece wear and become wear, known as chemical wear.

2. Phase change wear: When the cutting temperature reaches or exceeds the phase change temperature of the tool material, the metallographic structure of the tool material will change and the hardness will decrease significantly. This kind of wear is called phase change wear.

2. tool geometry angle and coating is also to pay special attention

1. Wear: When cutting, there is great pressure and strong friction between the chip, the workpiece and the front and rear cutter surfaces, resulting in new surface contact and cold welding combination. Due to the shear failure of the chip during the sliding process, the tool material is taken away, resulting in adhesive wear.

2. Diffusion wear: At high cutting temperature, the tool wear caused by the mutual diffusion and replacement of alloying elements in the workpiece and tool material becomes diffusion wear.

Strengthening of Cutting Edge of 3. Tool

Hard point wear of non-standard tool manufacturers: when cutting, chips and workpiece materials contain some hard points, such as carbides, nitrides and oxides, as well as chip debris, which will leave scratches on the surface of the tool, which is a kind of wear.

4. reduce tool runout

U-groove milling cutter manufacturer: The radial runout of the standard tool is mainly caused by the radial cutting force. The radial cutting force intensifies the radial runout. Therefore, reducing the radial cutting force is an important principle to reduce the radial runout. There are several ways to reduce the radial runout:

1. Use a sharp and powerful knife.

2. U-groove milling cutter manufacturer: The rake surface of the tool should be smooth, which can reduce the friction of chips on the tool and the cutting force of the tool, thereby reducing the radial runout of the tool.

3. The taper hole and chuck of the spindle should be clean, and dust or debris should not be generated during the processing of the workpiece.

4. U-groove milling cutter manufacturer: When the tool feed is too small, the phenomenon of machining slippage will occur, resulting in the continuous change of the radial runout of the tool during machining, making the machined surface not smooth. When the tool feed is too large, the cutting force will become larger, resulting in larger tool deformation, larger radial runout of the tool during machining, and also making the machined surface not smooth.

5. When finishing, reverse milling is used, the cutting thickness is changed from small to large, and the tool load is also changed from small to large, so that the tool processing is stable.

6. U-groove milling cutter manufacturers: The rational use of cutting fluid aqueous solution with cooling effect has little effect on the cutting force, and the cutting oil with lubrication as the main function can significantly reduce the cutting force.

U-slot milling cutter manufacturers are introduced here today. Thank you for watching. Through the above introduction, I hope you can learn new knowledge. If you need to wash knives or drill bits, you can contact us U-slot milling cutter manufacturers. We are wholesalers and have certain guarantee in terms of price and quality. U-slot milling cutter manufacturers wish you a happy life.

keywords

Latest News

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved