News

The Positive Effect of Deep Hole Drill on Deep Hole Processing

Release time:

2022/06/20

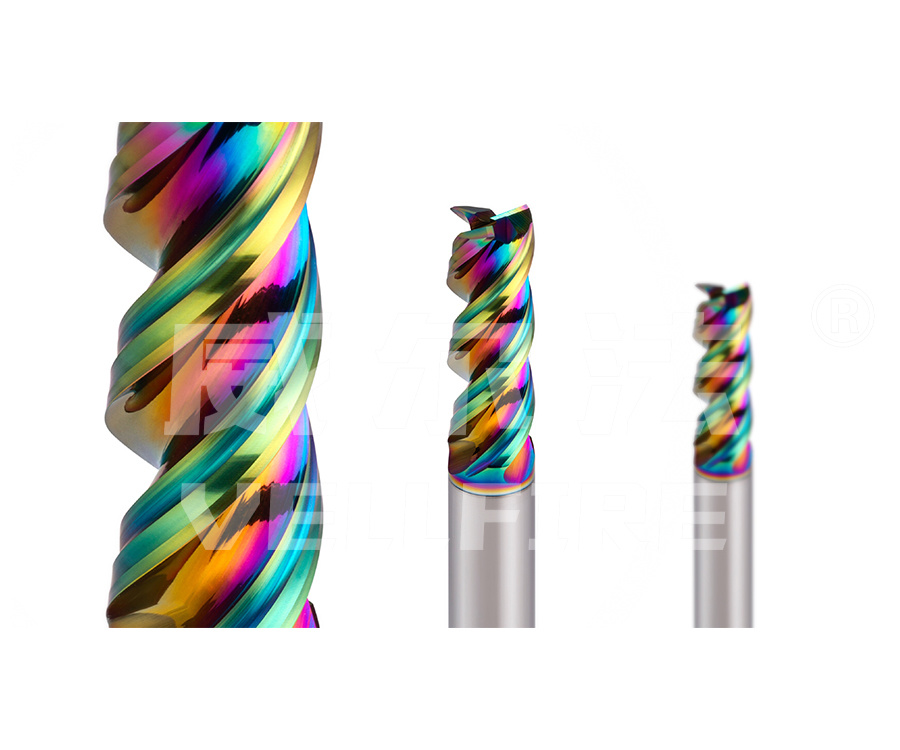

deep hole drill bitPositive effect on deep hole processing

The positive effect of deep hole drill bits on processing: When modern CNC basic processing deep hole drill bits, high-performance deep hole drill bits and high-pressure cooling systems are required.

In high alloy stainless steel and other medical equipment materials for deep hole drill cutting, through the high pressure discharge chip, to ensure the processing process.

Implant machining processes include turning, tapping, deep hole drilling, hexagonal milling, slitting and grinding. High-performance cutting oils are required if all processes are in one processing library.

When drilling a deep hole drill, starting from the pilot hole, the single-blade gun drill is supported by the guide block when drilling. ORTHO cutting oil greatly improves the quality of the workpiece surface.

In addition to this feature, the drilling accuracy is also improved. Otherwise, additional grinding is required. Eliminating this process can not only improve production efficiency and save costs. Modern deep hole drill is a high-precision, high-tech goods. These things produce valuable primary ingredients. The ideal connection of work tools, processes and industries actually extends the life of tools.

deep hole drill bitIt is a special equipment for processing deep hole workpieces. High precision, good rigidity.

Accurate depth display and depth control function. This function is particularly prominent when machining blind holes, stepped holes and other workpieces with depth requirements.

At the same time, the advantages that the product can be drilled and rolled are retained. The jacking of the workpiece and the top of the oil feeder are controlled by hydraulic pressure, which is safe and reliable and easy to operate. It is suitable for processing various hydraulic cylinders, spindle holes, cylinder holes and cooling holes.

What do I need to know when choosing a deep hole drill head?

The first point is that before choosing a deep hole drill head, you must first understand the variety and characteristics of the drill bit. Drills for printed boards include straight drills and fixed twist drills. The straight shank twist drill is basically used for single head drilling machine. At present, most of the CNC deep hole drill beds used by manufacturers use cemented carbide fixed drill bits, which can automatically change positions.

The second point is that when drilling deep holes, pay attention to the raw materials of the drill bit. The drill bit of the printed board is usually made of hard alloy, because the epoxy glass copper foil plate wears very quickly to the tool.

The third point is to choose a good deep hole drill head, choose a big brand, the quality is guaranteed. Now, there are many drill bit manufacturers. When choosing a deep hole drill head, you need to shop around and choose a big brand. Yes, the quality is good and very popular.

Deep hole drill bits are specially designed for processing deep holes. In machining, holes with a ratio of hole depth to diameter greater than 6 are usually called deep holes. In the process of deep drilling, the raw materials it uses are processed layer by layer, so its quality is guaranteed, and most of the materials it uses are iron. Iron has excellent rigidity and hardness, so the product has excellent impact resistance. In addition, in the process of commodity processing, it has the characteristics of fast production efficiency and high output value. This is inseparable from its drill function. It is capable of drilling any hard and functional commodity. Due to its durable function, it has good stability.

In deep hole processing, starting from the guide hole, the single-edged gun drill is supported by the guide block when drilling. ORTHO cutting oil greatly improves the quality of the workpiece surface. In addition to this feature, the drilling accuracy is also improved. Otherwise, additional grinding is required. Eliminating this process can not only increase productivity, but also save costs.

moderndeep hole drill bitIt is a high-precision, high-tech product. These tools can produce expensive and important parts. The ideal combination of tool, process and industry actually extends tool life.

keywords

Latest News

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved