News

Tungsten steel drill notes

Release time:

2022/07/28

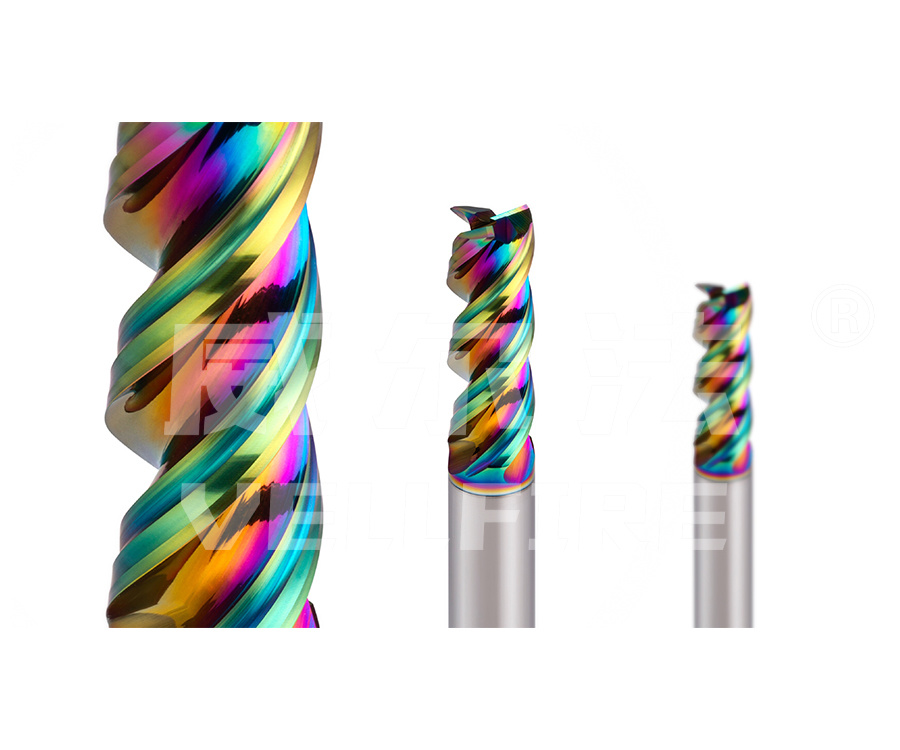

tungsten steel drill bitDo not know how to identify this material, what is tungsten steel drill? Tungsten steel products in the tungsten alloy content of about 18%, tungsten steel belongs to the hard alloy, also known as tungsten titanium alloy.

Do not know how to identify this material, what is tungsten steel drill? Tungsten steel products in the tungsten alloy content of about 18%, tungsten steel belongs to the hard alloy, also known as tungsten titanium alloy. It has 10K Vickers hardness, second only to diamond. Because of this, tungsten steel products (common tungsten steel watches) have the characteristics of not easy to wear. Commonly used turning tools, impact drill bits, glass cutter heads, tile knives, hard not afraid of annealing, but the quality is brittle. It is one of the rare metals.

When the tungsten steel drill bit and the ordinary drill bit or the white steel drill bit are weighed by hand, the tungsten steel drill bit is a bit heavy; when it is placed on an ordinary gray grinding wheel for grinding, the tungsten steel drill bit sparks are dark red and grinding is difficult. The sparks of ordinary or white steel rods are bright. Tungsten steel drill is fragile, from the hand to grab the ground, the edge of a collapse, the other drill is not broken. Tungsten steel drill bit has a series of excellent properties such as high hardness, wear resistance, good strength and toughness, heat resistance and corrosion resistance, especially its high hardness and wear resistance, even if it is basically unchanged at 500 ℃, it still has a high hardness at 1000 ℃.

tungsten steel drill bitIt is a solid material for drilling through or blind holes, and existing reaming tools. Generally speaking, our common tungsten steel drill bits mainly include twist drill, flat drill, center drill, deep hole drill and nesting drill. Reamers and sunken drills are usually classified as drill bits, although they cannot drill holes in solid materials.

So when we use tungsten steel drill bits, how should we operate and what should we pay attention?

1. When using tungsten steel drill bits, the chips should not be discharged in long strips. Especially in the processing of strong toughness of the material, too long chip will occur chip blockage, thereby damaging the tool. In this case, the feed is generally stopped, chip removal and then continue processing, this way is called segmented feed. In order to cut chips, metal shims can be installed in the chip groove section of the tungsten steel drill.

2. The second is the diameter of the drilling hole and the depth of the hole. The standard drilling depth is 5 times the diameter of the drill bit. If it is a tungsten steel blade type brazed on the shank, the depth can reach 7-8 times the diameter of the tungsten steel drill bit.

keywords

Previous Page

Next Page

Previous Page:

Next page:

Latest News

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved