News

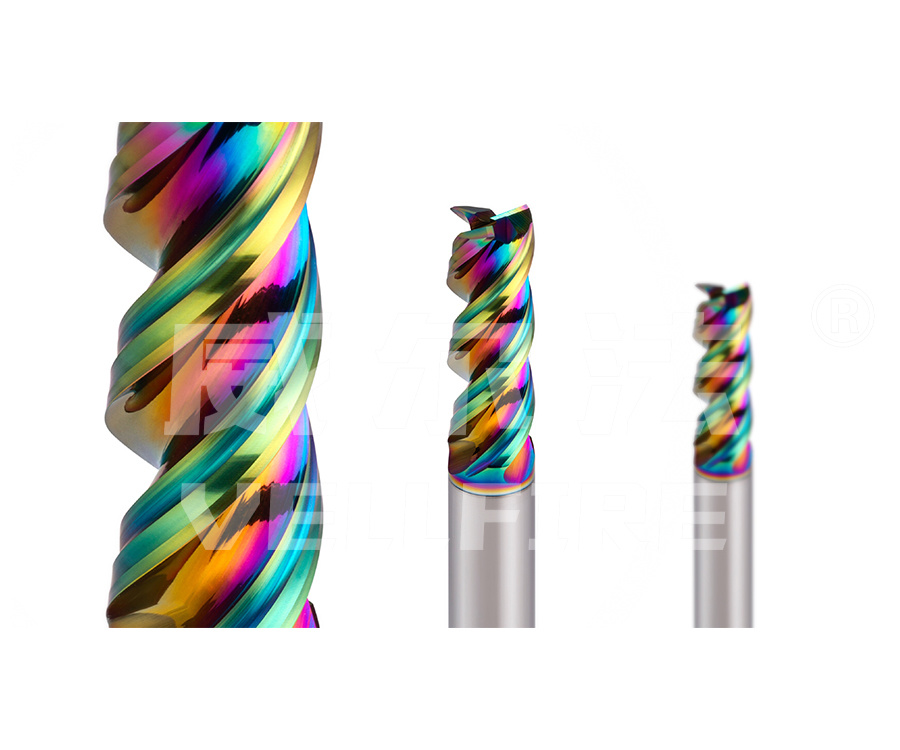

Dry goods sharing, one minute to take you to understand the U groove milling cutter

Release time:

2023/05/31

U-slot milling cutter is a commonly used metal processing tool, which is widely used in the cutting of sheet metal, but how to use this milling cutter correctly? The following are some precautions for U-slot milling cutters.

1. Milling cutter selection

U groove milling cutter selection should be based on the workpiece material, precision and other requirements, in order to achieve a good processing effect. At the same time, the milling cutter should be kept fully dry to avoid rust affecting the processing efficiency.

2. Preparation before processing

Before the U groove milling cutter processing, the machine tool should be cleaned and maintained, and the wear of the milling cutter should be checked. If there is any wear, it should be replaced in time. At the same time, it is necessary to adjust the cutting parameters, and select the cutting speed, feed and other parameters according to the specific requirements of the workpiece.

3. Precautions during processing

When using U-slot milling cutter, excessive feed should be avoided as far as possible to avoid serious wear of the milling cutter. When processing, the flatness of the surface of the workpiece should be ensured, and impurities such as chips and oil residue should be removed in time to reduce the contact area between the tool and the workpiece and reduce the cutting force.

4. Destruction and storage

The used U-slot milling cutters should be stored by classification to avoid mixing and wear. For milling cutters that have been worn out, they should be processed and destroyed in time to avoid other safety hazards caused by reuse.

5. Safe operation

When using U-slot milling cutter, you should strictly abide by the operating procedures and wear protective equipment to prevent accidental injuries. Especially in the replacement of milling cutters, cleaning machine tools and other operations, more care should be taken to ensure the safety of the operation.

6. Regular maintenance

After the U groove milling cutter has been used for a period of time, it should be cleaned and maintained regularly to ensure its normal service life and processing effect. Reducing the excessive wear of the tool can effectively reduce the processing cost and improve the processing quality of metal materials.

In short, as an important metal processing tool, U groove milling cutter needs to pay special attention to various details and safe operation during use to ensure its normal service life and processing effect. I hope the above content can be helpful to everyone.

U groove milling cutter is a more commonly used milling cutter, it has many advantages, the following for you to introduce in detail.

1. Effective

U groove milling cutter can easily complete high-speed machining, effectively improve production efficiency, save time and cost.

2. High precision

Due to its special U-shaped design, the U-slot milling cutter can better control the machining process and ensure machining accuracy. At the same time, the tip of the U-groove milling cutter can be fine-tuned, making it more convenient to operate.

3. Strong applicability

U groove milling cutter is suitable for the processing of many materials, such as: aluminum alloy, copper, stainless steel, titanium alloy, etc. Therefore, it not only facilitates production, but also saves costs.

4. Long service life

Excellent U groove milling cutter material production, through special process processing, can improve its hardness and toughness, reduce the wear rate, so that the service life is longer.

5. Economic and practical

The price of the U groove milling cutter is relatively reasonable and the service life is long, which can make the enterprise more practical and economically advantageous.

In short, U groove milling cutter has many advantages, such as effective, high precision, strong applicability, long service life and economical and practical, which is worth choosing and using by enterprises.

keywords

Latest News

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved