News

Sharing of Knowledge Points Related to U Groove Milling Cutter

Release time:

2022/04/06

According to the purpose, material and structure of the milling cutter, the milling cutter is divided into different types. The following is a brief introduction to common milling cutters:

1. Cylindrical milling cutter:

U-groove milling cutterManufacturer: The cutter teeth used to process the plane on the horizontal milling machine are distributed on the circumference of the milling cutter. According to the tooth profile, they can be divided into straight teeth and spiral teeth. According to the number of teeth, there are coarse teeth and fine teeth. The spiral tooth coarse tooth milling cutter has few teeth, high tooth strength and large chip space. It is suitable for rough machining and fine tooth milling cutter is suitable for finishing.

2. End face milling cutter:

U-groove milling cutter manufacturer: used for vertical milling machine end milling machine or gantry milling machine to process plane. There are cutter teeth on the end face and circumference, as well as coarse teeth and fine teeth. There are three structures: integral type, mosaic type and indexable type.

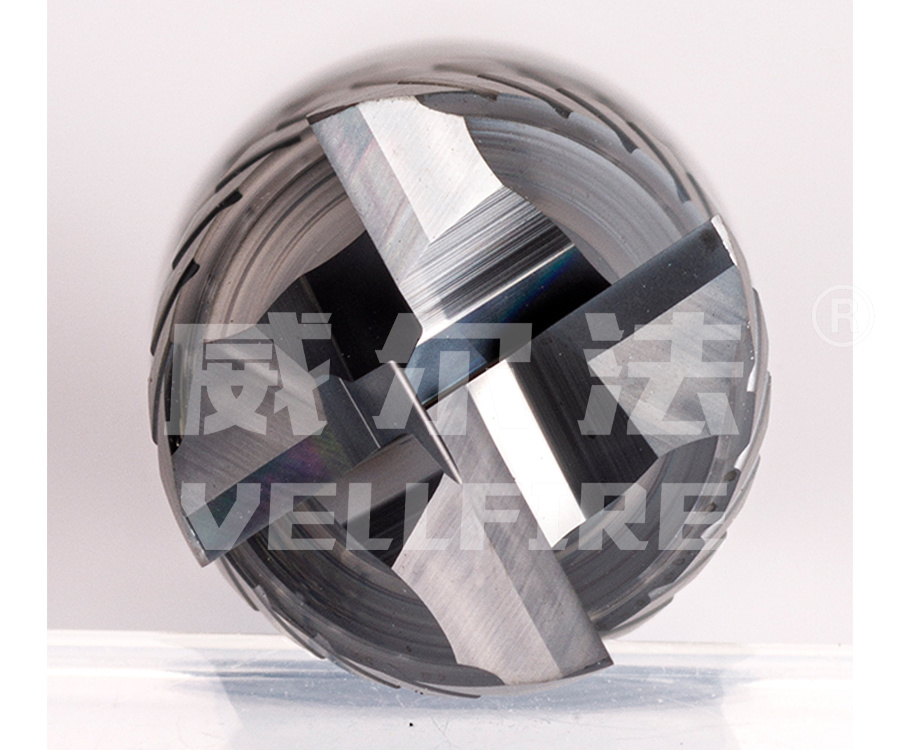

3. End milling cutter:

When machining the circumference and end face, the cutter teeth used for machining the groove and step face cannot be fed along the axial direction. When the end mill has an end tooth passing through the center, it can be fed axially (usually called double-edged end mill; Keyway milling cutter; Axial can be fed).

4. Three-sided milling cutter:

Used for processing various grooves and step surfaces, with cutter teeth on both sides and circumference.

U-groove milling cutter manufacturer: The radial runout of the standard tool is mainly caused by the radial cutting force. The radial cutting force intensifies the radial runout. Therefore, reducing the radial cutting force is an important principle to reduce the radial runout. There are several ways to reduce the radial runout:

1. Use a sharp and powerful knife.

2、U-groove milling cutterManufacturer: The rake surface of the tool should be smooth, which can reduce the friction of the chip on the tool and the cutting force of the tool, thereby reducing the radial runout of the tool.

3. The taper hole and chuck of the spindle should be clean, and dust or debris should not be generated during the processing of the workpiece.

4. U-groove milling cutter manufacturer: When the tool feed is too small, the phenomenon of machining slippage will occur, resulting in the continuous change of the radial runout of the tool during machining, making the machined surface not smooth. When the tool feed is too large, the cutting force will become larger, resulting in larger tool deformation, larger radial runout of the tool during machining, and also making the machined surface not smooth.

5. When finishing, reverse milling is used, the cutting thickness is changed from small to large, and the tool load is also changed from small to large, so that the tool processing is stable.

6. U-groove milling cutter manufacturers: The rational use of cutting fluid aqueous solution with cooling effect has little effect on the cutting force, and the cutting oil with lubrication as the main function can significantly reduce the cutting force.

U-groove milling cutterManufacturer: The price of tungsten steel saw blade milling cutter is generally composed of cemented carbide material cost, production and processing cost and reasonable profit. However, the saw blade milling cutter industry is different from the standard end milling cutter industry. It is difficult to give a price list. The price of milling cutter is mainly due to the following reasons:

1. There are many specifications of tungsten steel saw blade milling cutters. There is no so-called standard specification. Customers often ask us the price of a certain specification of saw blade milling cutter, saying it is standard. I usually say that this may be your industry. General or general specifications, but we will encounter various industries, and the number of specifications together is huge, so it is difficult to provide a unified price list.

2. The manufacturing process of the saw blade milling cutter is different from that of the end milling cutter. Generally, it needs to be clamped several times. The clamping positioning mainly depends on the inner hole. Therefore, there are many specifications of the inner hole and many clamping and positioning fixtures are required. If the inner hole specification is not common, the price is higher than that of the ordinary saw blade milling cutter of the same size.

3. The teeth of the saw blade milling cutter have many different requirements, some are V-shaped teeth, some are angle teeth, the processing technology is different, the price is also different.

4. Processing parts: different machining parts have different choices, steel parts and non-ferrous metals are different.

5. The saw blade milling cutter can be used alone or in combination. If the combined use always requires the size of multiple saw blades, the price will be different.

keywords

Previous Page

Next Page

Previous Page:

Next page:

Latest News

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved