News

Related Knowledge Sharing of Tube Plate Drill

Release time:

2022/04/15

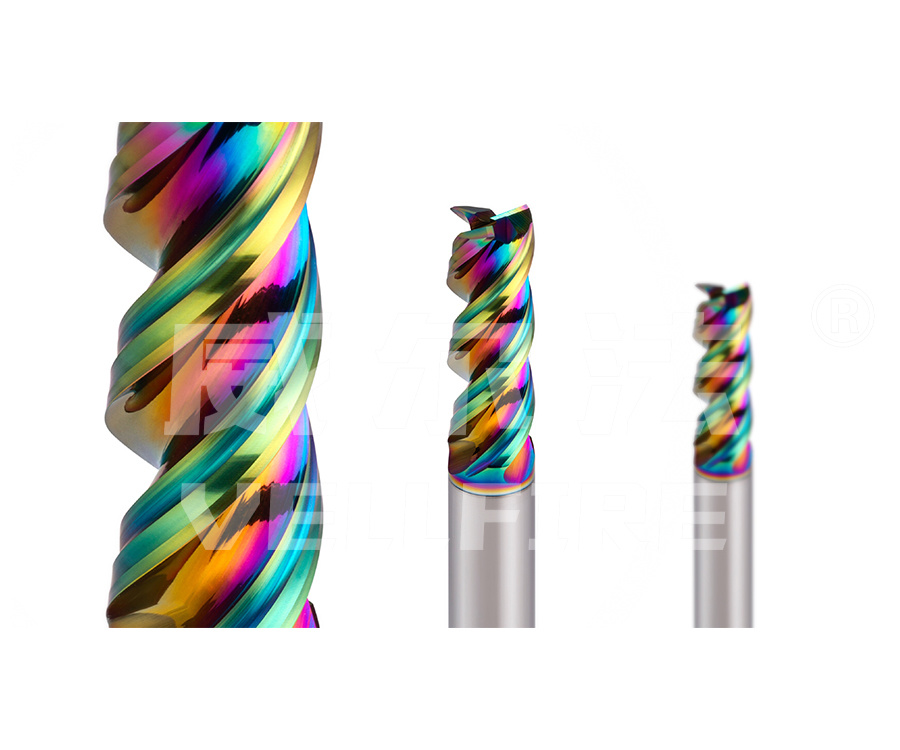

Tube sheet bitThe difficulty of processing is an important factor restricting the manufacturing cycle and cost of heat exchanger. Ordinary drill not only has low processing efficiency, but also is difficult to solve the problems in deep hole processing, and the strength and heat dissipation performance of the tool tip can not meet the processing requirements of this special case.

What should be paid attention to in the process of tube sheet drill bit processing operation:

Tube sheet drill: The chip groove adopts double-edged chip groove, which can reduce the width of the chip without changing the feed rate and increase the thickness of the chip. According to the cutting principle, the influence of the width of the chip on the cutting force is greater than the thickness of the chip. Therefore, under the same cutting area, thin and thick chips are more labor-saving than thin and wide chips. The chips are cut straight and the chip discharge speed is fast, which can bring out some fine ribbon chips and reduce the friction and pressure between chips and the hole wall. The space occupied by the straight chips is small, which is conducive to the entry and exit of the coolant. Then drill with a parabolic groove drill, than the twist drill has many advantages.

Tube sheet bitThe core becomes thicker and the rigidity of the drill bit increases; secondly, the helix angle becomes larger, the chip groove becomes wider, the chip holding space of the chip groove becomes larger, and the cooling condition is improved. When sharpening, the knife tip adopts the cross sharpening method. Shorten the chisel edge and reduce the axial force; the part of the drill bit adopts the form of group drilling, so that the angle of the front surface becomes larger. The double-edged chip causes the narrow chip to be expelled in a straight line along the root of the chip groove of the drill bit.

Tube sheet bit technology to achieve the elements:

In order to overcome this problem, the tube sheet drill bit welds the tube and tube sheet at a specified angle before perforation, finds the cavity and virtual hole, obtains the actual angle of the tube and tube sheet after welding deformation, and fuses the data obtained from the virtual hole with the three-dimensional structure diagram of the actual size of the workpiece, so as to determine the position of the hole to provide the basis for the adjustment of processing parameters in the future, realize the reversibility of inclined tube perforation processing, and improve the processing accuracy and efficiency.

The beneficial effects are as follows.

1) Provide the inclined tube perforation processing method on the tube sheet, simple operation, easy control of conditions, low cost, and wide application range;

2) The inclined tube perforation processing method of the tube plate adjusts the coaxiality of the perforation by welding the solid tube and the tube plate into a whole, so as to avoid the occurrence of errors and reduce the difficulty of operation;

3) The provided method for perforating the inclined tube on the tube plate determines the angle with the tube plate through virtual perforation, thereby improving the processing accuracy.

4) Provide a three-dimensional structure by fusing virtual processing data and the actual size of the workpiece, which can foresee the results of drilling processing, adjust the processing parameters according to the results, realize reversible processing, effectively improve the processing efficiency and reduce the loss of the tube plate.Tube sheet bitProcessing methods.

keywords

Previous Page

Latest News

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved