News

Precautions for titanium alloy milling cutter

Release time:

2022/05/21

titanium alloy milling cutterPrecautions? We also made a brief introduction to this issue before, but found that there are still many customers who do not understand. Today, I also take this opportunity to explain to you. Hope can bring good help for the relevant people.

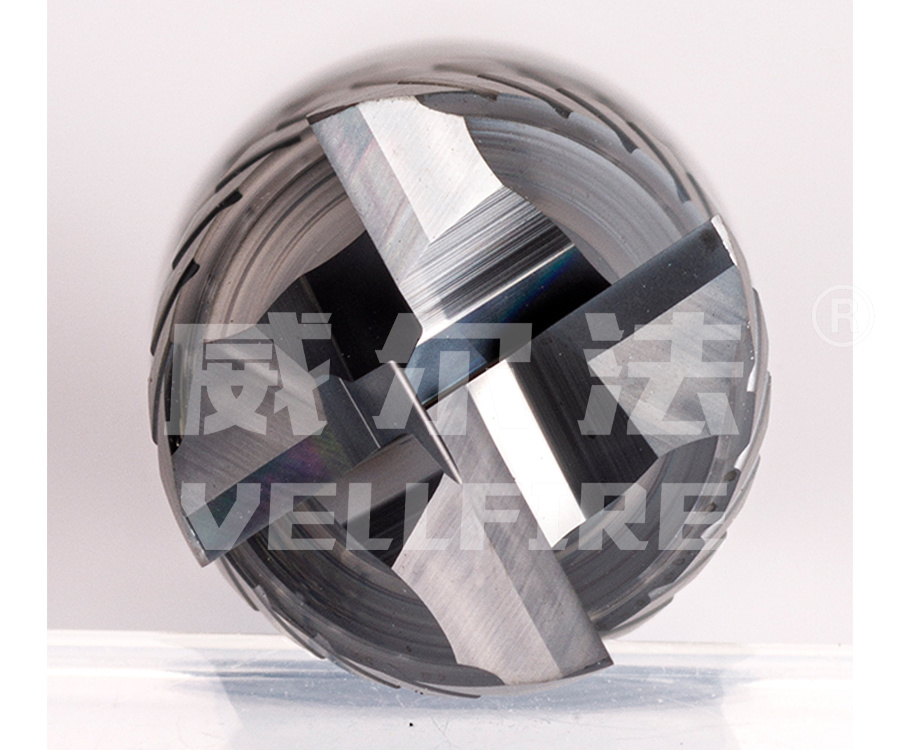

Titanium alloy milling cutter in the milling process, it will cut the chip at the same time, itself will be worn and blunt. And titanium alloy milling cutter it in the blunt to a certain extent, if you continue to use, then it will lead to a significant increase in the milling force and cutting temperature, so we need to know that the amount of wear will also be rapidly increased, thus affecting the machining accuracy and machining surface quality and the utilization rate of milling cutter. For the user, we need to know that the location of its tool wear mainly occurs in the front and back of the blade and its vicinity. The wear of the milling cutter is dominated by the wear of the back face and the edge of the blade. If you explain this way, I believe everyone will understand. For these basic knowledge points, at least we will know what it is when we see it. Of course, its advantages are more. And it's all reflected in different places. Titanium alloy milling cutter is still in use when this problem is due to the chip or workpiece friction surface has a tiny hard point, so it will be in the tool to carve out the depth of the groove, resulting in mechanical wear.

It is recommended that everyone use it.titanium alloy milling cutterYou must also pay attention to it. Sometimes the harder the workpiece material, the stronger the ability of the hard particles to scratch the surface of the tool. So what you need to know is that its titanium alloy milling cutter wear has a more obvious effect on high-speed tool steel tools. We should pay attention to it after we have said it here today. Of course, to improve the grinding quality of titanium alloy milling cutter, reduce the surface roughness value of the front, back and blade, can slow down the mechanical wear of the milling cutter. Titanium alloy milling cutter when it is in use, we also need to know that the temperature rises due to the generation of cutting heat. In this way, the hardness of its tool material decreases due to phase transformation caused by temperature increase. If it is adhered to the chip and the workpiece and taken away by adhesion, adhesive wear will occur. And under the action of high temperature, the product will also diffuse and replace the alloy elements of the workpiece material. Under such circumstances, the mechanical properties of the tool will be reduced, and diffusion wear will occur under the action of friction. If you have something you don't understand, you can call us at any time for advice.

The content of the above article is to introduce the relevanttitanium alloy milling cutterIf you don't know these things, come and learn them quickly, hoping to bring help to more friends, and the next issue will bring more wonderful content. If you don't understand anything, you can consult us at any time.

keywords

Previous Page

Previous Page:

Latest News

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved