News

On the Wear of Titanium Alloy Milling Cutter

Release time:

2022/05/24

titanium alloy milling cutterIt can be said that in the industrial automation industry has a very important role, in order to make everyone more familiar with it, the next small series for small partners to tell about the wear of titanium alloy milling cutter it.

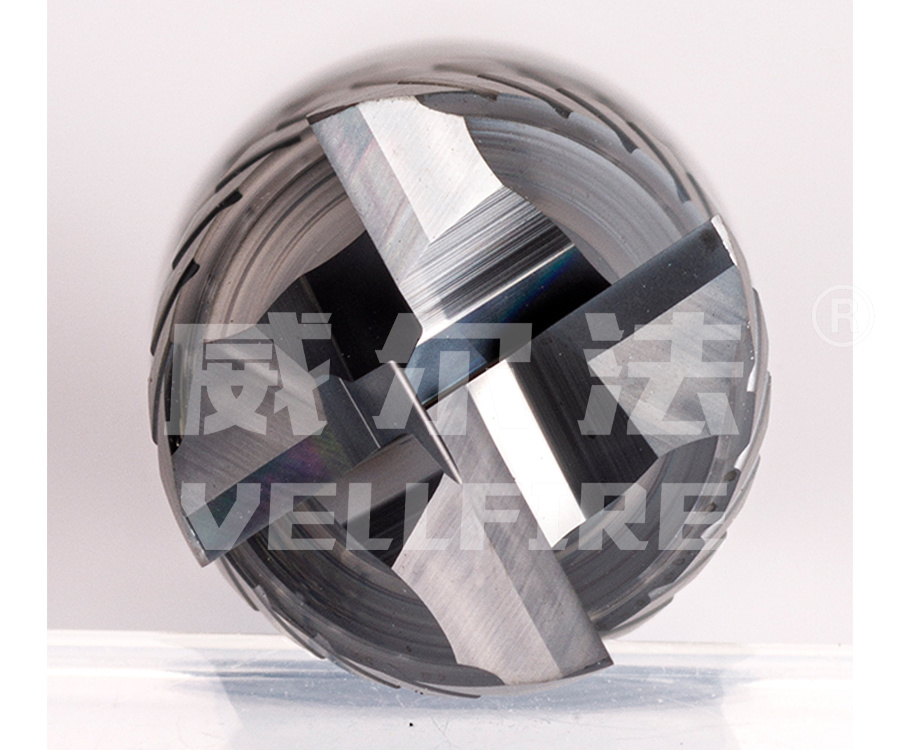

The structure of the titanium alloy milling cutter is very compact, and it is also very beautiful from its appearance. The operation of this equipment is also very simple. But also accompanied by a lot of problems. For example, titanium alloy milling cutter, like other cutting tools, with the growth of cutting time, its wear process can be divided into three stages. First of all, that is the initial wear stage. In fact, this stage is relatively fast. Of course, the main reason for this literature and art is that after the titanium alloy milling cutter is sharpened, the convex peaks and burrs on the blade produced by the grinding marks of the grinding wheel on its surface are quickly smoothed in a short period of time. When you use it, you need to pay attention to the fact that if the convex peaks are large and the burrs are serious, the wear amount is large. This is to improve the grinding quality of the milling cutter, and to polish the blade and the front and back with grinding or oilstone. Only by doing these well can the wear in the initial stage be effectively reduced. If there are any questions you don't understand, you can call us at any time for consultation. There are online customer service personnel to receive you, no matter what questions will help you patiently to answer.

In addition, everyone is usingtitanium alloy milling cutterWhen also need to pay attention to is its normal stage, in fact, this time it is relatively slow, the amount of cutting time with the growth of uniform and stable increase. However, if you are using a titanium alloy milling cutter for a period of time, it will make its blade blunt after a long period of use, making the milling force larger, the cutting temperature higher, and the milling conditions worse. When you use a titanium alloy milling cutter, the speed will rise sharply, the wear rate will increase sharply, and this tool will quickly lose its cutting ability. When using milling cutters, avoid milling cutter wear into this stage. If there are these problems in the actual use of titanium alloy milling cutter, then the surface roughness value of the machined surface is obviously larger than the original, so that it will make the surface of the bright spot and scale thorn; the cutting temperature is obviously increased, when the chip is cut, its color changes; the cutting force becomes larger, and even vibration phenomenon. We also remind everyone here that it needs to be removed for sharpening and cannot continue milling.

The above article content is small make up for everyone to introducetitanium alloy milling cutterIts wear and tear problem, about other knowledge points will continue to be updated in the next period, I hope you can bring you some substantive help in the future, here welcome to establish long-term cooperative relations with friends from all over the country.

keywords

Latest News

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved