News

Some related knowledge of titanium alloy milling cutter

Release time:

2022/09/02

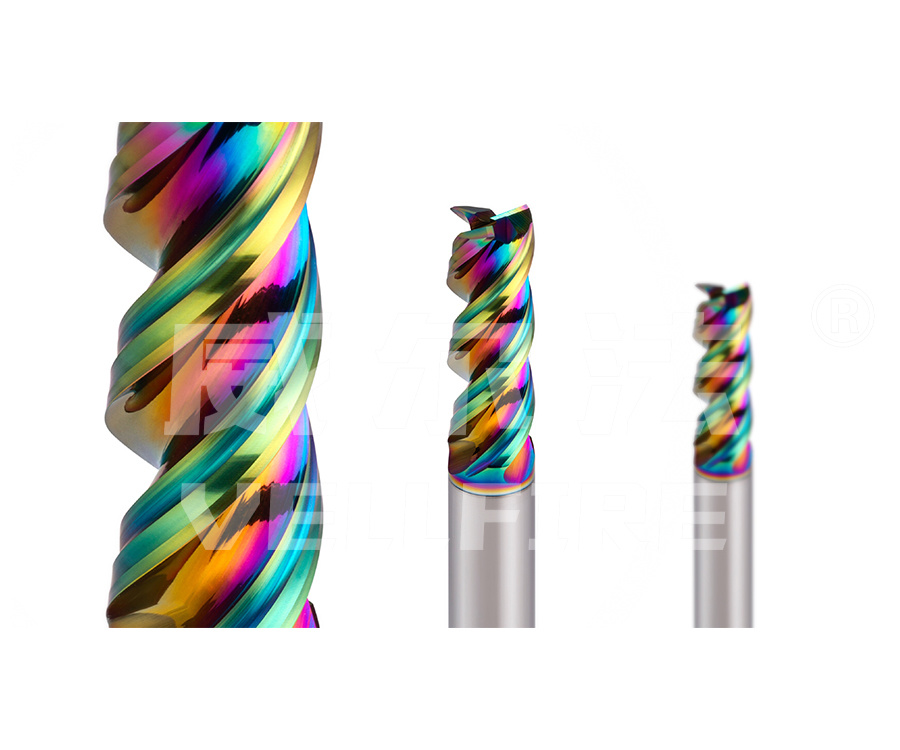

Do you knowtitanium alloy milling cutterWhat is it? What is its function? I believe most of my friends still don't understand these problems. However, we do not throw too anxious, today this article mainly for you to tell about some of the relevant knowledge of titanium alloy milling cutter?

If you are also interested in this topic, then look down with the editor. I hope you can bring some better help when choosing after seeing it. Although the titanium alloy milling cutter is now used in many industries, but most people will feel strange when they see it. When using, we need to know that with the advancement of industrial technology in recent years, the improvement of machine tool performance and the continuous improvement of cutting accuracy, the use of ordinary steel milling inserts on machine tools can no longer meet the needs. At present, we also see that high-speed steel, hard alloy or ceramic materials have been widely used abroad to manufacture new high-speed, high-precision and impact-resistant composite milling cutters and composite ultra-precision milling cutters made of high-speed steel and hard alloy. In addition, we also need to know that due to the limitation of capital and technical level, ordinary carbon structural steel is still the main tool material in China's machine tool manufacturing industry. In recent years, some domestic enterprises have developed various grades of stainless steel, high-temperature heat-resistant aluminum alloys and other new materials for rough machining and finishing of machine tools; but in general,titanium alloy milling cutterIts scope of application is still very narrow and its development is slow. Therefore, in order to change this situation as soon as possible, it is necessary to accelerate the development of high-performance metal-based non-metallic materials.

In addition, aluminum-based composites, copper-based composites and nickel-based powder metallurgy materials are replacing traditional high-performance metal materials. Among them, titanium alloy with excellent comprehensive performance has attracted people's attention, mainly because it is a new member of the non-metallic material family after iron-nickel metal. It has high strength, high hardness and low strength. It not only has good mechanical properties and corrosion resistance, but also is cheap and easy to obtain. Therefore, titanium alloy milling cutter is widely used in the manufacture of aero engine parts and other important parts. In short, you should know that titanium alloy is a conductor with poor thermal conductivity. Compared with steel, its coefficient is 10. During the cutting process, 75% of the heat generated by the processing will be transferred to the tool and will not be discharged with the chips. In order to solve this problem, people need to use high heat-resistant hard metal materials, titanium alloy milling cutters and take effective cooling measures during processing. This will result in the use of a large amount of coolant, which is recommended to enter the cutting surface directly through the spindle under high pressure. Therefore, for titanium alloy cutting operations, titanium alloy milling tools with internal cooling of the carrier tool has become the product of choice.

The above article content is for each friend to telltitanium alloy milling cutterSome of the relevant knowledge, I hope it can bring you help.

keywords

Latest News

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved