News

What are the advantages of titanium alloy milling cutter?

Release time:

2022/09/14

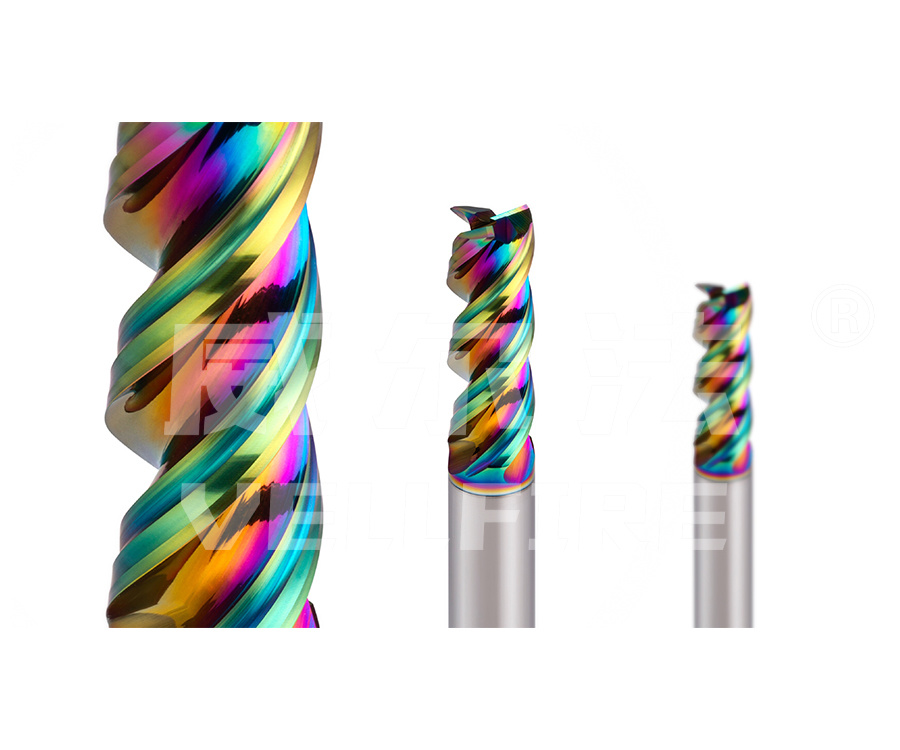

titanium alloy milling cutterThe development prospects of this industry is very good, because in the use of the benefits for the enterprise more, so by the customers of all ages, in order to let you more of it, then we come to talk about the advantages of titanium alloy milling cutter What are the hope to bring help to more people.

Nowadays, there are still many people who do not know some basic information about titanium alloy milling cutters, so as a manufacturer, it is necessary for us to explain briefly. In fact, the main feature of this titanium alloy milling cutter is that it can process various metals (including various hardened steels) and non-metals (such as marble and jade bones), and process workpieces with high hardness. The handle can be used to replace the small grinding wheel in most of the work without dust pollution. The processing quality is good, especially its high smoothness, and it can process various high-precision mold cavity shapes. Long service life, 10 times more durable than high-speed steel tools and 200 times more durable than small grinding wheels. In addition, what we say to you is that it is easy to master during operation, simple to use, safe and reliable, which can reduce labor intensity and improve working environment. High economic benefits, comprehensive processing costs can be reduced by about 10 times. The titanium alloy milling cutter we are talking about today is a carbide rotary file, which is generally driven by hand-held electric or pneumatic tools (can also be used for machine tools). The rotation speed of electric or pneumatic tools is generally 6000-50000 RPM. Clamping is required for tool use. Reverse milling is a better cutting method to avoid the tool walking back and forth. Avoid flying debris when working. Please wear protective glasses.

titanium alloy milling cutterThe whole is made of high-speed steel. The spiral blade is distributed on the cylinder surface and has no auxiliary blade. The spiral cutter teeth gradually cut people and leave the workpiece during the cutting process, so the cutting process is relatively stable. Most of them are used on horizontal milling machines to process narrow planes and long planes with a width less than the length of the milling cutter. In addition, it should be understood that according to different processing requirements, titanium alloy milling cutters can be divided into coarse teeth and fine teeth. The coarse teeth have a larger pinch groove for roughing and the fine teeth for finishing. When the outer diameter of the milling cutter is relatively large, it is usually made into an insert. The main cutting edge of the face milling cutter is scattered on the cylindrical or conical surface, the end cutting edge is the auxiliary cutting edge, and the axis of the titanium alloy milling cutter is parallel to the machining surface. Then, during the operation, according to the material of the tool teeth, it can be divided into high-speed steel and cemented carbide. A complete set of gear insert structure was produced, and the material of the cutter body was 40Cr. Titanium alloy milling is widely used because of its fast milling speed and good appearance quality. It can also process workpieces with hard skins and hardened layers. According to the different installation methods of the blade and cutter teeth, the carbide face milling cutter can be divided into integral type, machine clamp welding type and indexation type.

After the introduction of the above content, we are also right.titanium alloy milling cutterThe advantages of further understanding. When I see him again in the future, I will not feel strange, and there will be no frequent problems in the process of using it. Well, that's all for today's content. I believe it will bring more wonderful knowledge points.

keywords

Latest News

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved