News

Detailed explanation of the main purpose of titanium alloy milling cutter

Release time:

2022/09/26

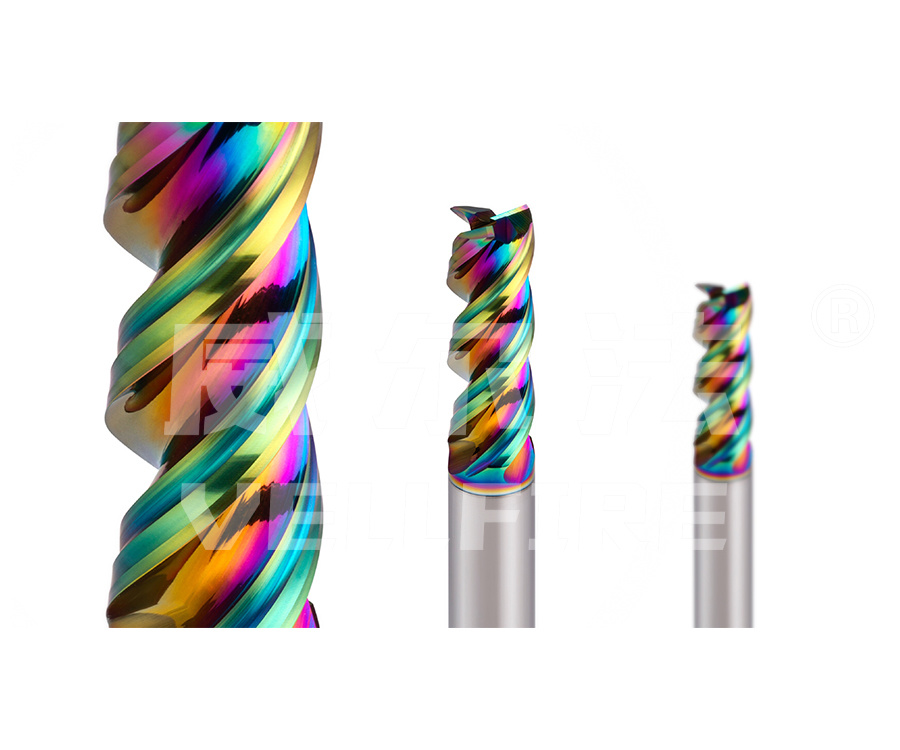

titanium alloy milling cutterWe can see from its name that this equipment is used to do, in fact, you need to know that this product is also after continuous improvement of the function more and more, in order to let more people familiar with it, the next small series for everyone to introduce the type and use of titanium milling cutter.

The alloy milling cutter has low density and high strength, so its specific strength (σb/ρ) is greater than that of ultra-high strength steel. In particular, it has good thermal stability, high temperature strength, and can work for a long time at 500°C, while aluminum alloy can only work below 200°C. The strength of titanium alloy at 300-500 ℃ is about 10 times that of aluminum alloy. In addition, alloy milling cutters can work for a long time in humid atmosphere and seawater media, and their corrosion resistance is far better than stainless steel. It has strong resistance to pitting corrosion, acid corrosion and stress corrosion. Alloy milling cutters have excellent corrosion resistance to alkali, chloride, chlorine organic compounds, nitric acid and sulfuric acid. However, titanium has poor corrosion resistance to reduced oxygen and chromium salt media. What we need to know is that titanium reacts strongly with O, N, H, Co, CO2, water vapor and nitrogen in the atmosphere. When the carbon content is more than 0.2%, a hard tic is formed in the titanium alloy. When the temperature is high, if it interacts with nitrogen, it will also form a hard surface layer of tin. Above 600 ℃, titanium can absorb oxygen to form a hard layer. Here is a good manufacturer of beer on the Internet. The company's official website has a variety of different products. Consumers' evaluation of it is quite high. And on the company's official website, it also contains a lot of information about products, as well as shopping tips and so on.

In fact,titanium alloy milling cutterThe increase of hydrogen content will also form a hardened layer: the hard and brittle surface depth generated by titanium absorbing gas can reach 0.1-0.15mm, and the hardening degree is 20%-30% higher than that of the matrix. The chemical affinity of titanium is also great, and it is easy to combine with the friction surface. In particular, it has a low thermal conductivity and a small modulus of elasticity: titanium has a very low thermal conductivity of 15.24 w/m · K, which is equivalent to 1/4 of nickel, 1/5 of iron and 1/4 of aluminum. The thermal conductivity of various titanium alloys is low, generally 50% of titanium. At the same time, the titanium alloy milling cutter coating also produces an effective thermal protection layer, which can protect hard metal materials from premature wear during high-speed cutting. In addition, the coating material has undergone a special surface treatment to achieve a smooth cutting surface, so that the titanium alloy milling cutter greatly reduces the friction coefficient during the cutting process. This will result in the use of a large amount of coolant, which passes directly into the cutting surface through the spindle under high pressure. Thus, load bearing tools with internal cooling have become a product for titanium alloy cutting operations. If consumers want to buy this type of product, remember to shop around. This is an era of information technology. There is no need for everyone to go to the market to work hard. You can directly search for manufacturers related to Han Rong's parts on the Internet.

The above article content we tell you about the relevanttitanium alloy milling cutterIf you don't know the main purpose of the, then come and have a look. That's all about this knowledge. I hope I can help you.

keywords

Latest News

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved