Unleashing Peak Performance

VELLFIRE Precision Cutting Solutions

Why VELLFIRE High Performance Tools

Superior Material Performance

Made of high quality tungsten steel, it can withstand extreme pressure and keep the edge sharp even under the working condition of HRC60° or below.

Precision Engineering Design

Non-equal tooth pitch design and molded groove technology dramatically reduce vibration, optimize chip removal efficiency, and achieve ±0.01mm machining accuracy.

Wide Applicability

Perfectly adapted to stainless steel, titanium alloy, high-temperature alloy and hardened steel, capable of dynamic side milling, grooving and powerful roughing.

Rapid Response

Full specification coverage and direct factory supply from the source shorten the delivery cycle and help the tight production schedule.

Core Advantages, Achieve Industry Leadership

1. Top grade tungsten steel material:

strictly selected material extends tool life by 30% and reduces machining cost per piece.

2. micron-level process:

exclusive grinding technology ensures zero defects in surface finish and dimensional consistency.

3. One-stop customization:

full specification coverage - one-stop procurement, from standard to non-standard tool design, tailored to solve special machining challenges.

4. Free Optimized Solutions:

Cost savings of 30%+!

5. Agile delivery:

Factory direct supply, average 7-day delivery cycle - speed and quality at the same time.

Customized Services

Customization Process

20 years experience in precision alloy machining.

01

Demand communication

02

Product Customization

03

Production & Delivery

04

After-sales Tracking

20000+ Successful Cases

Popular Products Recommended

Popular products recommended (UX/NX/LX/WX and other series).

Large Inventory

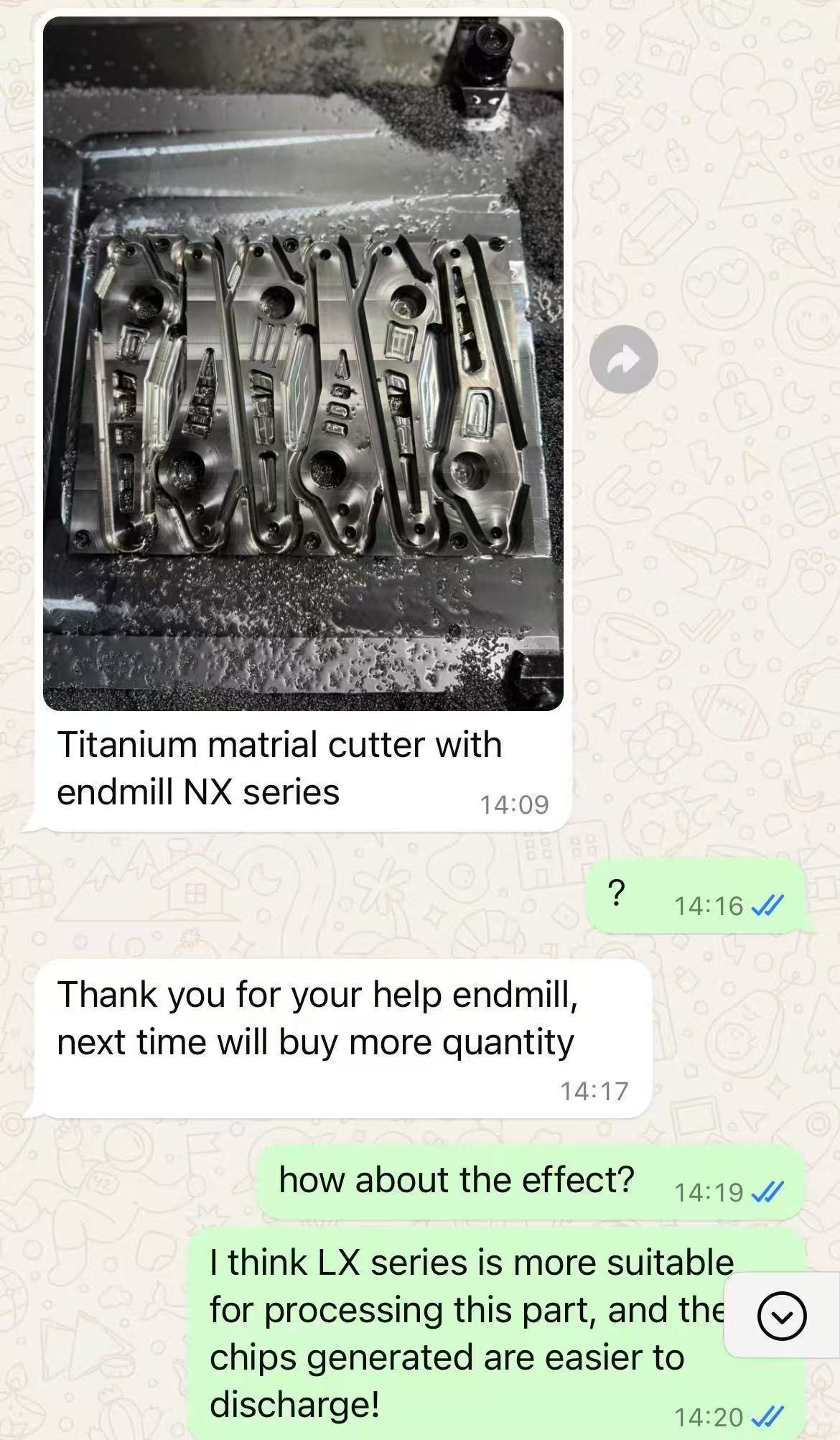

What Does Our Customer Say

Customer Evaluation Scroll bar 06

Customer Evaluation Scroll bar 05

Customer Evaluation Scroll bar04

Customer Evaluation Scroll bar03

Customer Evaluation Scroll bar02

Technical Support

Pre-sales Selection Guide

- Material hardness comparison table

- Cutting parameters calculation tool.

After-sales support

- Online technical Q&A: response within 24 hours.

- Tool tutorial videos:

- Library of Frequently Asked Questions

After-sales commitment

- Free replacement within the warranty period

- Urgent order expedited production:

FAQ

Which milling cutters are recommended for aerospace machining?

Open roughing can be done with the LX series high efficiency violent roughing cutters.

Finishing cuts can be made with the N X series titanium recutting cutters.

How do we guarantee the quality of cutting tools?

All factory cutting tools will be 100% size and appearance of the full inspection, we have the world's most advanced Zoller G3 testing equipment, size inspection are within tolerance before shipment.

How to ship?

Standard series (in stock) will be shipped within 7 days, and customized non-standard tools will be shipped within 15 days.

How to choose the type of milling cutter to use?

If the hardness of workpiece is below HRC55°, you can use our UX, NX, LX series for side milling (dynamic milling).

If the hardness of the workpiece is above 55°HRC, you can use our WX series for end milling and laminating.

What is the difference between high speed tool steels(HSS) materials and tungsten carbide materials?

Tungsten carbide material is better than high speed tool steels(HSS) material regarding the characteristics of Hardness, the temperature of Heat Resistance, Wear Resistance, Deflection Resistance(Young's modulus) etc., and is applicable for harder work materials than high speed tool steels(HSS) material, is possible to mill with high velocity. However, tungsten carbide material is brittle because of its high hardness. So there are some cases that tungsten carbide material has chipping easier than high speed tool steels(HSS) material when the end mills receive shock during milling.

What is important and recommended milling condition with using micro diameter end mills?

It is very important to control spindle run-out on applying micro diameter end mills. If the spindle run-out is getting bigger, tools can be damaged easily and the quality of milled surface becomes worse. Regarding the milling conditions, please set it without chatter vibration. And it is effective to set it with small milling amount and high feed rate for applying micro diameter end mills.

Is it possible to produce milling cutters and drills with irregular sizes (diameters)?

It can be produced.We as a professional high-end tungsten steel cutting tool manufacturer normal manufacturer, please contact our sales person in charge.

What is the scale of your company?

Our factory is located in Wujin, Jiangsu Province. Since 2000, we have been selling to domestic market (50%), Middle East (15%), Southeast Asia (15%), Europe (10%), North America (10%).

Factory Strength

Founder's Introduction

Xue Bin

CEO

As the founder of Jiangsu Wilfa Precision Alloy, has been engaged in the cutting tool manufacturing industry for more than 20 years, leading the company's team to research and develop, design, produce and manufacture more than 100 patented cutting tools, serving 20,000+ users.

Cutting-edge Application Scenarios

Aerospace

Efficient slotting of titanium components.

Automotive manufacturing

Powerful rough milling of mold steel to accelerate prototype development.

Energy

Precision machining of high-temperature alloy turbine blades.

About VELLFIRE

Join the global industry leader of choice and trust Jiangsu VELFIRE Precision Alloys to reinvent your machining processes.

Jiangsu Vellfire Precision Alloy Co., Ltd. provides integrated tool solutions! Integrating professional production, development and design, market sales, and customer service; Provide high-quality, cost-effective and efficient re cutting milling cutters, with efficient fast feed for drill bits.

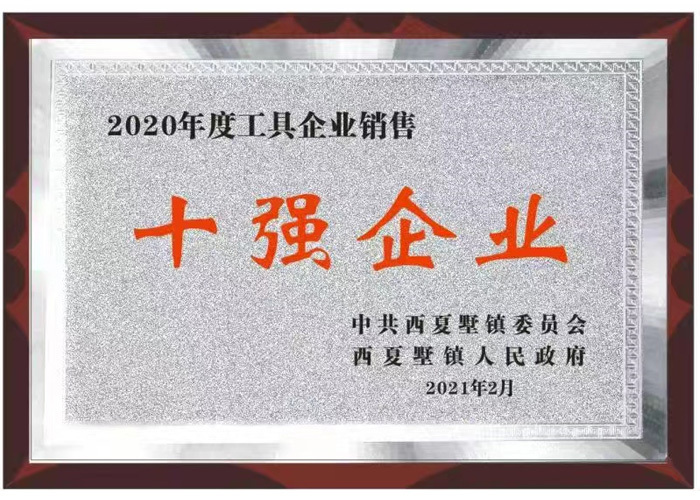

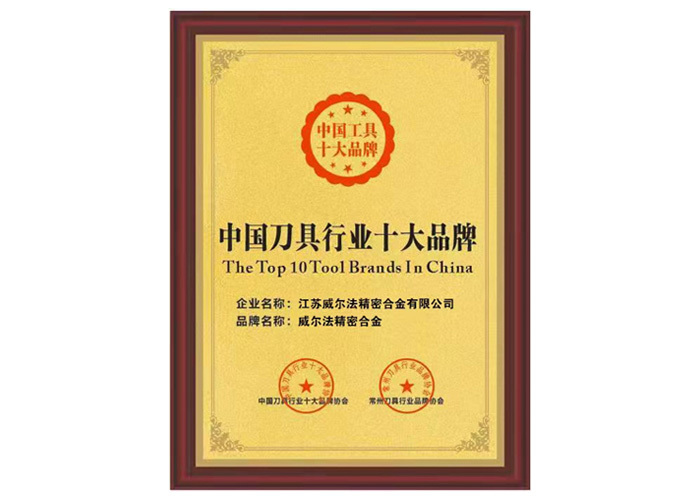

Factory strength

Graphene industrial park production base, advanced CNC equipment show.

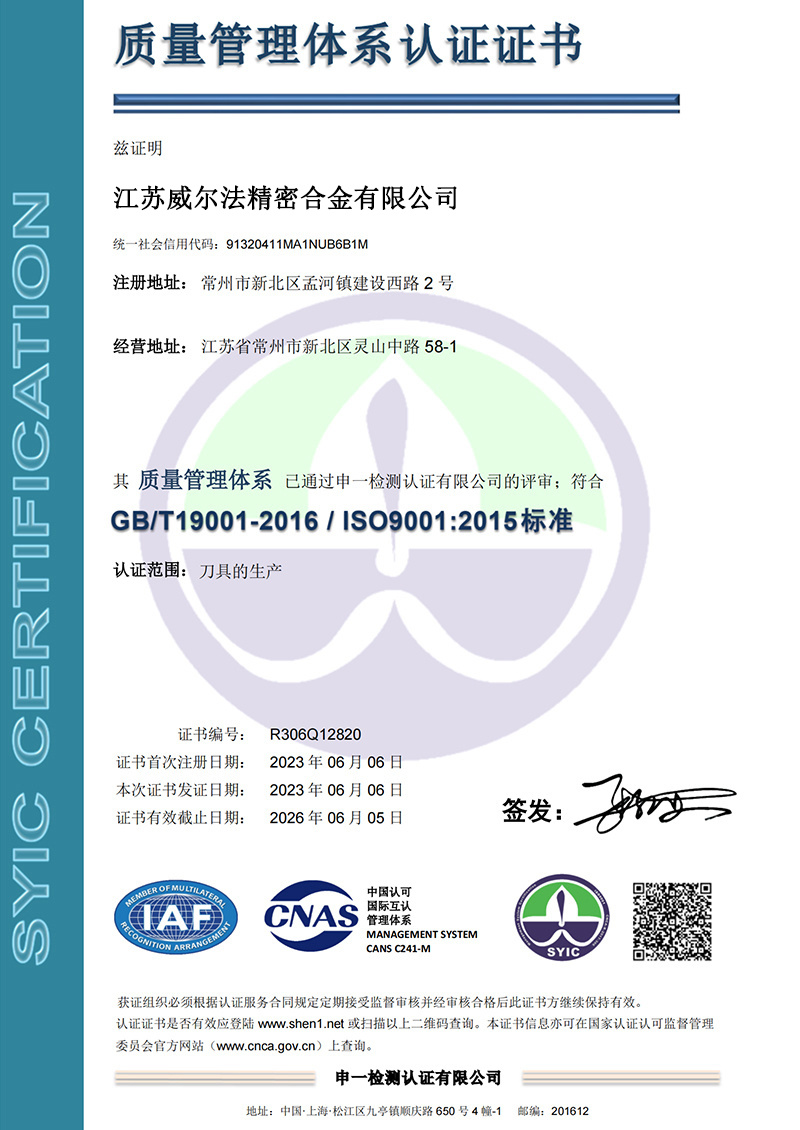

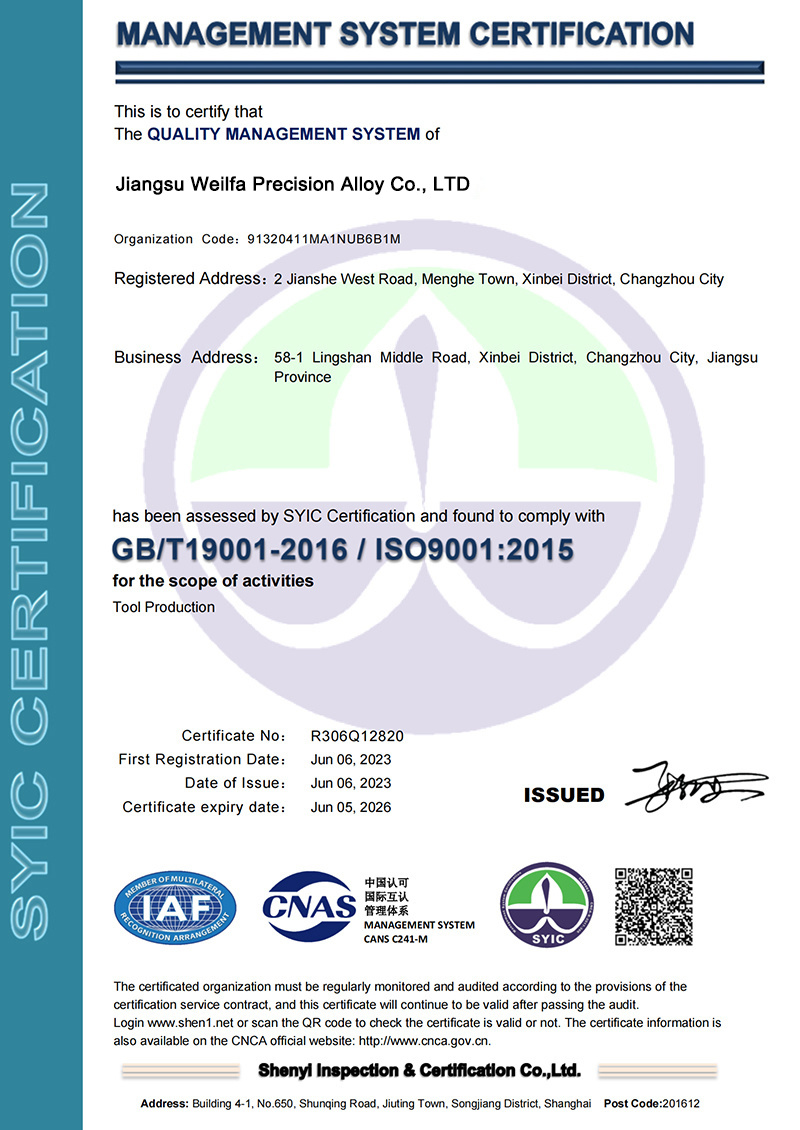

Qualification

ISO9001, patent certificate, etc.

Team Introduction

Team Introduction: Sales Director & Senior Engineer (such as Xue Bin) and other professional support.

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved