VELLFIRE PRODUCT

Products

COMPANY PROFILE

One-stop Tool Solutions And Custom Design Services

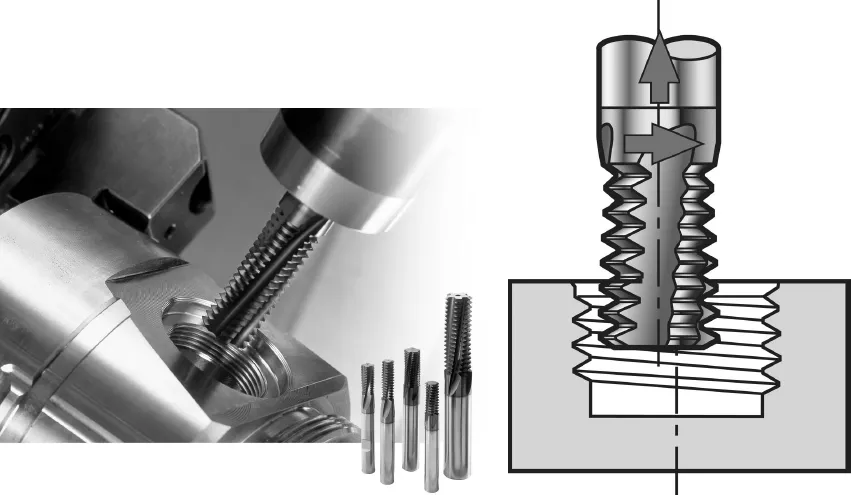

Jiangsu Vellfire Precision Alloy Co., Ltd. integrates professional production, development and design, marketing and customer service; it provides high-quality, cost-effective and efficient re-cutting milling cutters, and efficient fast-feed drill bits. At the same time, it provides tool solution, undertakes high-quality drill bits, milling cutter passivation business, high-performance CNC machine tools, coating services, tool regrinding services and project design services.

VELLFIRE ADVANTAGE

Will Method Advantage

Years of industry experience

Will method precision alloy set professional production, development and design, marketing and sales, customer service in one.

Product quality assurance

Through strict production standards, unique tool design and rich production experience, we provide reliable guarantee for tool quality.

Customized solutions

Provide tool solutions, undertake high-quality drill business and project design services.

Worry-free after-sales service

The company has long provided unparalleled quality services to customers of major manufacturing enterprises.

GLOBAL MARKETING

Global Marketing Network

The main products are UX series economical end mills, NX series stainless steel (steel parts) high-efficiency re-cutting milling cutters, LX series violent rough milling cutters, WX series high hardness mold knife, RC series cost-effective colorful aluminum milling cutters, GS series cost-effective drill bit. Through unremitting pursuit of product quality and customer efficiency, the company has long provided unparalleled quality services to customers of major manufacturing enterprises, its products have been sold in many countries and regions around the world.

View More →

NEWS INFORMATION

News

Understanding the Hidden Threat of Tool Runout in Precision Machining

Tool Wear in Machining: Causes, Impacts, and Effective Solutions

Advanced Ceramic Cutting Tools Revolutionize Modern Manufacturing

Partners

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved