Products

WX series 750 high hardness mold round nose knife

HRC55 ° ~ 75 ° high hardness

Product Characteristics:

HD multilayer high hardness coating

The newly developed HD multi-layer high hardness coating, heat-resistant layer wear-resistant layer and other multi-layer coatings significantly improve the processing life of the tool.

Ultrafine particle cemented carbide

The bar is made of 0.3um ultrafine particle cemented carbide, which has ultra-high wear resistance and strength, and obtains ultra-high processing life in the high-speed processing of high-hardness materials.

Product Details

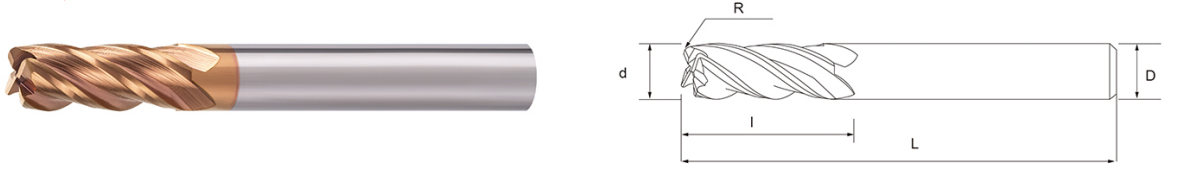

R angle arc protection designR angle rake face arc protection design, eliminate stress points, improve processing life

|

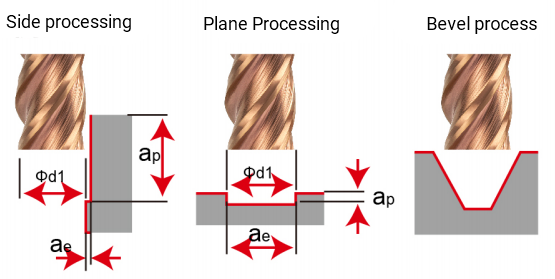

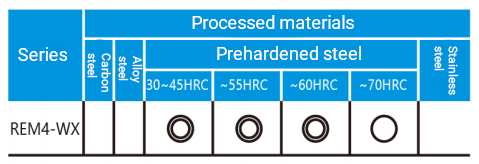

Scope of applicationSuitable for 50- 70HRC high hardness steel processing Suitable for coarse and fine integrated processing

|

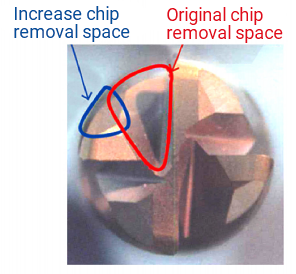

Large chip removal space designThe large chip removal space design makes the tool chip removal space larger and the processing efficiency is higher

|

Product Model

| Blade diameter (d) | R diameter (R) | Blade length (I) | Shank diameter (D) | Total length (I) | Blade number (F) |

| 1 | 0.1 | 3 | 4 | 50 | 2 |

| 1 | 0.2 | 3 | 4 | 50 | 2 |

| 1 | 0.3 | 3 | 4 | 50 | 4 |

| 1.5 | 0.2 | 4 | 4 | 50 | 4 |

| 1.5 | 0.3 | 4 | 4 | 50 | 4 |

| 2 | 0.2 | 5 | 4 | 50 | 4 |

| 2 | 0.3 | 5 | 4 | 50 | 4 |

| 2 | 0.5 | 5 | 4 | 50 | 4 |

| 2.5 | 0.2 | 6 | 4 | 50 | 4 |

| 3 | 0.2 | 8 | 4 | 50/75 | 4 |

| 3 | 0.3 | 8 | 4 | 50/75 | 4 |

| 3 | 0.5 | 8 | 4 | 50/75 | 4 |

| 3 | 1 | 8 | 4 | 50/75 | 4 |

| 4 | 0.2 | 10/15 | 4 | 50/75 | 4 |

| 4 | 0.3 | 10/15 | 4 | 50/75 | 4 |

| 4 | 0.5 | 10/15 | 4 | 50/75 | 4 |

| 4 | 1 | 10/15 | 4 | 50/75 | 4 |

| 4 | 1.5 | 10/15 | 4 | 50/75 | 4 |

| 5 | 0.2 | 13 | 6 | 50 | 4 |

| 5 | 0.3 | 13 | 6 | 50 | 4 |

| 5 | 0.5 | 13 | 6 | 50 | 4 |

| 5 | 1 | 13 | 6 | 50 | 4 |

| 6 | 0.2 | 15/20 | 6 | 75/100 | 4 |

| 6 | 0.3 | 15/20 | 6 | 75/100 | 4 |

| 6 | 0.5 | 15/20 | 6 | 75/100 | 4 |

| 6 | 1 | 15/20 | 6 | 75/100 | 4 |

| 6 | 1.5 | 15/20 | 6 | 75/100 | 4 |

| 6 | 2 | 15/20 | 6 | 75/100 | 4 |

| 8 | 0.3 | 20/25 | 8 | 60/100 | 4 |

| 8 | 0.5 | 20/25 | 8 | 60/100 | 4 |

| 8 | 1 | 20/25 | 8 | 60/100 | 4 |

| 8 | 1.5 | 20/25 | 8 | 60/100 | 4 |

| 8 | 2 | 20/25 | 8 | 60/100 | 4 |

| 8 | 2.5 | 20/25 | 8 | 60/100 | 4 |

| 8 | 3 | 20/25 | 8 | 60/100 | 4 |

| 10 | 0.3 | 25/30 | 10 | 75/100 | 4 |

| 10 | 0.5 | 25/30 | 10 | 75/100 | 4 |

| 10 | 1 | 25/30 | 10 | 75/100 | 4 |

| 10 | 1.5 | 25/30 | 10 | 75/100 | 4 |

| 10 | 2 | 25/30 | 10 | 75/100 | 4 |

| 10 | 2.5 | 25/30 | 10 | 75/100 | 4 |

| 10 | 3 | 25/30 | 10 | 75/100 | 4 |

| 12 | 0.3 | 30/35 | 12 | 75/100 | 4 |

| 12 | 0.5 | 30/35 | 12 | 75/100 | 4 |

| 12 | 1 | 30/35 | 12 | 75/100 | 4 |

| 12 | 1.5 | 30/35 | 12 | 75/100 | 4 |

| 12 | 2 | 30/35 | 12 | 75/100 | 4 |

| 12 | 2.5 | 30/35 | 12 | 75/100 | 4 |

| 12 | 3 | 30/35 | 12 | 75/100 | 4 |

Support non-standard specification customization

Keywords: WX series 750 high hardness mold round nose knife

Online Message

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved