Products

LX series high efficiency violent rough milling cutter

Below HRC55 °

Product Characteristics: It is suitable for high speed and high feed violent processing of general steel parts, stainless steel, titanium alloy, superalloy and kovar alloy.Product Details

Versatility super,Suitable for most materials;Especially suitable for high-efficiency side milling.

TA composite coatingThe newly developed composite coating based on TiAIN is an excellent lubricity coating with smoother chip removal and can be widely used in the processing of multi-clock materials. Shank diameter tolerance H6 |

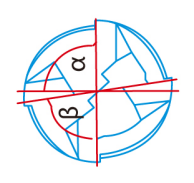

Unequal designa≠ β Unequal blade design, specially designed for steel parts; Large unequal design, suppression of tool vibration; High efficiency cutting at the same time, improve the finish of the processing surface.

Design of circular arc chip breaking grooveThe arc chip-breaking groove eliminates the stress concentration point, and the iron chips are broken in high-speed processing while improving the processing efficiency.

Special wave distance designEnhanced chipping resistance.

Sharp rake special wave designFor steel rake angle design, cutting sharpness, spindle load small chip breaking design waveform, even if the viscous material processing, the same performance.

Fine particle cemented carbideThe bar stock is made of the preferred cemented carbide material, which has excellent wear resistance and chipping resistance. |

Product Model

| Blade diameter (d) | Blade length (I) | Shank diameter (D) | Total length (I) | Blade number (F) |

| 6 | 15 | 6 | 50 | 4 |

| 8 | 20 | 8 | 60 | 4 |

| 10 | 25 | 10 | 75 | 4 |

| 10 | 30 | 10 | 75 | 4 |

| 10 | 40 | 10 | 100 | 4 |

| 12 | 30 | 12 | 75 | 4 |

| 12 | 45 | 12 | 100 | 4 |

| 14 | 40 | 14 | 100 | 4 |

| 16 | 45 | 16 | 100 | 4 |

| 20 | 45 | 20 | 100 | 4 |

Support non-standard specification customization

Recommended cutting conditions

Groove milling-rough milling

| Processing material |

Cast iron, carbon steel |

Alloy Steel |

Pre-hardened steel |

Aluminum alloy, copper |

Stainless Steel |

Duplex stainless steel |

Titanium alloy |

Nickel base alloy |

||||||||

| Cutting speed (m/min) | 110(90-130) | 100(80-120) | 80(60-100) | 200(180-220) | 70(50-80) | 40(20~50) | 60(50-70) | 25(20-30) | ||||||||

| Diameter | Revolutions | Feed | Revolutions | Feed | Revolutions | Feed | Revolutions | Feed | Revolutions | Feed | Revolutions | Feed | Revolutions | Feed | Revolutions | Feed |

| 6 | 5760 | 790 | 5184 | 707 | 4608 | 489 | 10368 | 2829 | 3552 | 468 | 2016 | 187 | 3072 | 468 | 1248 | 146 |

| 8 | 4320 | 728 | 3840 | 655 | 3456 | 458 | 7680 | 2621 | 2688 | 364 | 1536 | 146 | 2304 | 364 | 960 | 135 |

| 10 | 3360 | 593 | 3072 | 530 | 2688 | 374 | 6144 | 2122 | 2112 | 333 | 1248 | 146 | 1824 | 364 | 768 | 135 |

| 12 | 2880 | 572 | 2592 | 520 | 2304 | 364 | 5184 | 2080 | 1824 | 312 | 1056 | 156 | 1536 | 343 | 643 | 114 |

| 16 | 2112 | 478 | 1920 | 406 | 1728 | 312 | 3936 | 1664 | 1344 | 239 | 768 | 125 | 1152 | 291 | 480 | 94 |

| 20 | 1728 | 416 | 1536 | 364 | 1392 | 260 | 3168 | 1456 | 1056 | 198 | 624 | 104 | 960 | 260 | 384 | 83 |

| Cutting depth | ap:1D | |||||||||||||||

Side milling-efficient milling

| Processing material |

Cast iron, carbon steel |

Alloy Steel |

Pre-hardened steel |

Aluminum alloy, copper |

Stainless Steel |

Duplex stainless steel |

Titanium alloy |

Nickel base alloy |

||||||||

| Cutting speed (m/min) | 140(120-160) | 120(100-140) | 100(80-120) | 250(180-220) | 70(60-80) | 40(30~50) | 70(60-80) | 25(20-30) | ||||||||

| Diameter | Revolutions | Feed | Revolutions | Feed | Revolutions | Feed | Revolutions | Feed | Revolutions | Feed | Revolutions | Feed | Revolutions | Feed | Revolutions | Feed |

| 6 | 7152 | 1456 | 6221 | 936 | 5184 | 655 | 12768 | 3640 | 3552 | 468 | 2016 | 239 | 3552 | 468 | 1248 | 146 |

| 8 | 5376 | 1248 | 4608 | 832 | 3840 | 582 | 9600 | 3328 | 2688 | 364 | 1536 | 187 | 2688 | 364 | 960 | 135 |

| 10 | 4272 | 1144 | 3686 | 676 | 3072 | 510 | 7680 | 2704 | 2112 | 364 | 1248 | 187 | 2112 | 364 | 768 | 135 |

| 12 | 3552 | 1040 | 3110 | 676 | 2592 | 468 | 6432 | 2704 | 1824 | 343 | 1056 | 187 | 1824 | 343 | 643 | 114 |

| 16 | 2688 | 780 | 2304 | 520 | 1920 | 364 | 4800 | 2080 | 1344 | 270 | 768 | 146 | 1344 | 270 | 480 | 94 |

| 20 | 2112 | 624 | 1824 | 437 | 1536 | 291 | 3840 | 1664 | 1056 | 239 | 605 | 114 | 1056 | 239 | 384 | 83 |

| Cutting depth | ap: 2D ae:0.3D | |||||||||||||||

Remarks:

1, Please use a rigid machine tool, fixture and handle.

2. Please adjust the speed and feed according to the actual cutting depth and equipment rigidity.

3. If vibration or noise occurs, please reduce the speed and feed in the same proportion.

4. Air cooling is recommended for high hardness steel and cast iron, and water-soluble cutting fluid is recommended for other materials.

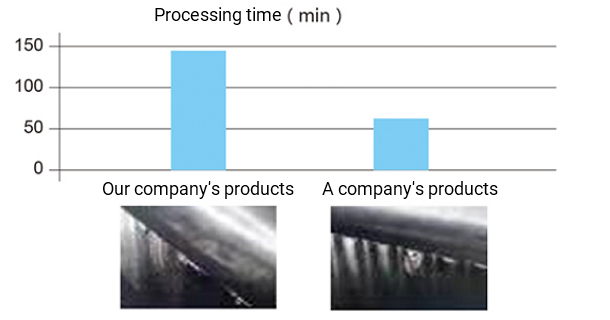

Machining Case 1 (Groove Machining)

| Using tools | LX-D10*25*75*4T |

| Processing materials | 42CrMo(HB180-220) |

| Processing mode | Roughing of side edge |

| Cutting speed | 151 m/min(4800min-1) |

| Feed speed | 1100mm/min(0.0573mm/Fz) |

| Cutting depth | Ap=15.0mm Ae=2mm |

| Cooling mode | Water-soluble cutting fluid |

| Use of machine tools | Vertical machining center (BT50) |

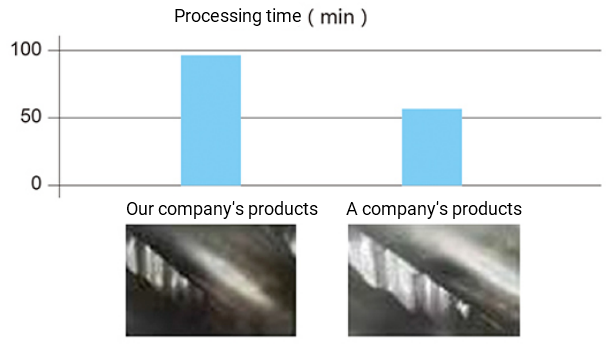

Processing case two (side edge rough machining)

| Using tools | LX-D6*15*50*4T |

| Processing materials | 42CrMo(HB180-220) |

| Processing mode | Roughing of side edge |

| Cutting speed | 131 m/min(7000min-1) |

| Feed speed | 1100mm/min(0.039mm/Fz) |

| Cutting depth | Ap=15mm Ae=2mm |

| Cooling mode | Water-soluble cutting fluid |

| Use of machine tools | Vertical machining center (HSK50A) |

Keywords: LX series high efficiency violent rough milling cutter

Online Message

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved