Products

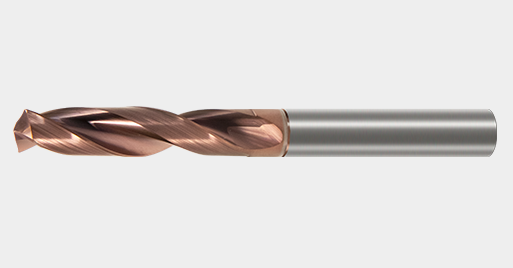

GS series economic efficiency drill bits

Economic efficiency drill bit

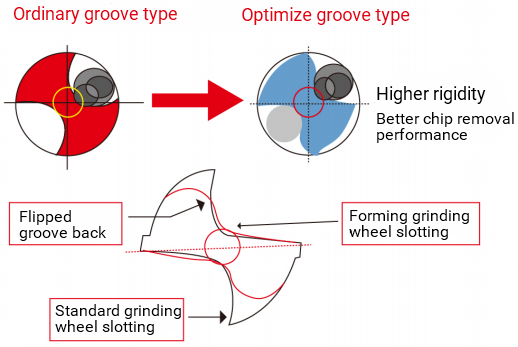

Product Characteristics:Optimized groove shape

Higher rigidity more excellent chip removal performance.

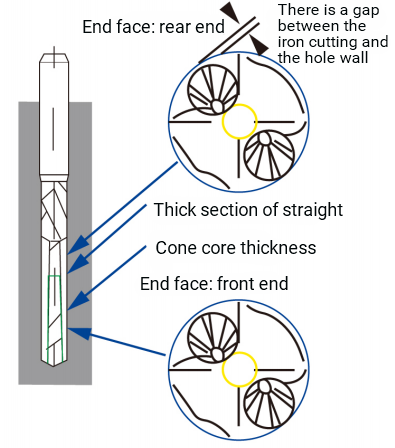

Special trough design

Under the same row of eyebrow space, a larger core thickness diameter can be obtained, so as to achieve high efficiency and long life drilling.

Product Details

|

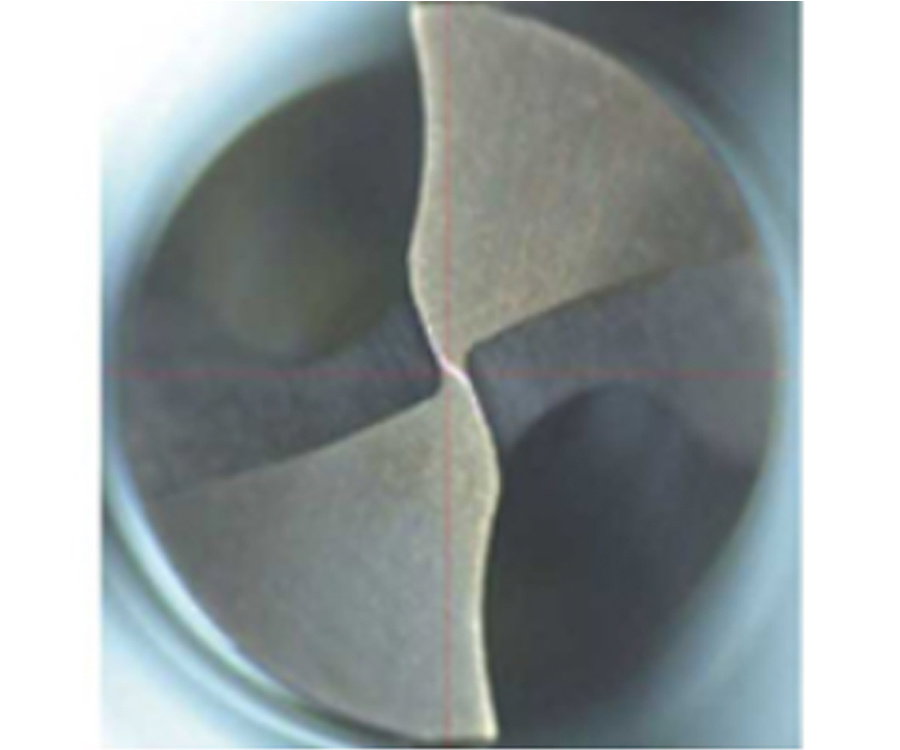

The function curve arc chip holding groove can obtain a shorter curled iron chip shape, smooth chip removal, not easy to block, and improve the processing life while ensuring stability!

|

Special trough designUnder the same chip removal space, a larger core thickness diameter can be obtained, thereby achieving high efficiency and long life drilling.

|

Product Model

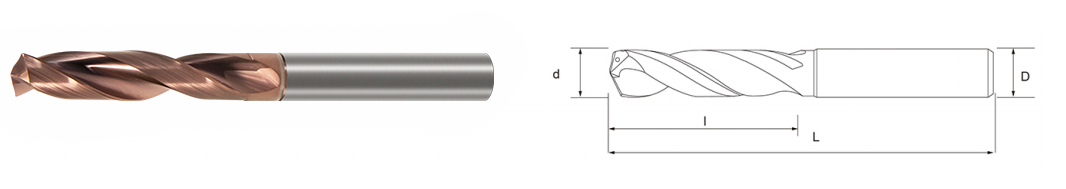

3D twist drill (Internal cooling/external cooling)

| diameter(d) | Slot length(l) | Shank diameter (D) | Total length(L) |

| D3.00-D3.70 | 20 | 6 | 62 |

| D3.80-D4.70 | 24 | 6 | 66 |

| D4.80-D6.00 | 28 | 6 | 66 |

| D6.10-D7.00 | 34 | 8 | 79 |

| D7.10-D8.00 | 41 | 8 | 79 |

| D8.10-D10.0 | 47 | 10 | 89 |

| D10.1-D12.0 | 55 | 12 | 102 |

| D12.1-D14.0 | 60 | 14 | 107 |

| D14.1-D16.0 | 65 | 16 | 115 |

| D16.1-D18.0 | 73 | 18 | 123 |

| D18.1-D20.0 | 79 | 20 | 131 |

Support non-standard specification customization

5D twist drill (Internal cooling/external cooling)

| diameter(d) | Slot length(l) | Shank diameter (D) | Total length(L) |

| D3.00-D3.90 | 28 | 6 | 66 |

| D4.00-D4.70 | 36 | 6 | 74 |

| D4.80-D6.00 | 44 | 6 | 82 |

| D6.10-D8.00 | 53 | 8 | 91 |

| D8.10-D10.0 | 61 | 10 | 103 |

| D10.1-D12.0 | 71 | 12 | 118 |

| D12.1-D14.0 | 77 | 14 | 124 |

| D14.1-D16.0 | 83 | 16 | 133 |

| D16.1-D18.0 | 93 | 18 | 143 |

| D18.1-D20.0 | 101 | 20 | 153 |

Support non-standard specification customization

|

Important Reminder: This parameter is for reference only, please according to the actual drill bit specifications, Processing conditions and customer specific requirements to make appropriate adjustments, In case of doubt or anomalies, Please contact our technical personnel in time, thank you! |

|

External cold

| Processing material | General steel, carbon steel | Alloy steel | Tempered steel, die steel | |||

| SS400 S45C (200HB) | SCM440,42CrMo (200-300HB) | SKD61 (30-40HRC) | ||||

| Outer diameter D (mm) | Cutting speed F (mm/min) | Feed rate f (mm/rev) | Cutting speed F (mm/min) | Feed rate f (mm/rev) | Cutting speed F (mm/min) | Feed rate f (mm/rev) |

| 4 | 40-60-80 | 0.06-0.08-0.15 | 40-50-60 | 0.06-0.07-0.15 | 20-30-40 | 0.06-0.08-0.1 |

| 6 | 0.1-0.13-0.15 | 0.1-0.12-0.15 | 0.06-0.09-0.15 | |||

| 8 | 0.1-0.16-0.18 | 0.12-0.15-0.2 | 0.08-0.1-0.15 | |||

| 10 | 0.15-0.2-0.25 | 0.15-0.18-0.25 | 0.1-0.12-0.15 | |||

| 12 | 0.2-0.23-0.3 | 0.15-0.2-0.25 | 0.1-0.15-0.18 | |||

| 16 | 0.25-0.28-0.3 | 0.2-0.25-0.3 | 0.15-0.18-0.2 | |||

| Processing material | Gray cast iron | Ductile iron | Stainless Steel | |||

| FC250 (250HB) | FCD450 (300HB) | SUS304、SUS316 (~200HB) | ||||

| Outer diameter D (mm) | Cutting speed F (mm/min) | Feed rate f (mm/rev) | Cutting speed F (mm/min) | Feed rate f (mm/rev) | Cutting speed F (mm/min) | Feed rate f (mm/rev) |

| 4 | 50-60-70 | 0.08-0.1-0.15 | 40-50-60 | 0.07-0.09-0.15 | 30-40-50 | 0.06-0.08-0.13 |

| 6 | 0.1-0.15-0.2 | 0.15-0.13-0.2 | 0.08-0.1-0.15 | |||

| 8 | 0.15-0.2-0.25 | 0.15-0.18-0.25 | 0.1-0.12-0.15 | |||

| 10 | 0.2-0.25-0.3 | 0.15-0.2-0.25 | 0.1-0.15-0.2 | |||

| 12 | 0.2-0.27-0.35 | 0.2-0.23-0.3 | 0.15-0.18-0.2 | |||

| 16 | 0.25-0.3-0.35 | 0.2-0.25-0.3 | 0.15-0.2-0.25 | |||

Internal cold

| Processing material | General steel, carbon steel | Alloy Steel | Tempered steel, die steel | |||

| SS400 S45C (200HB) | SCM440,42CrMo (200-300HB) | SKD61 (30-40HRC) | ||||

| Outer diameter D (mm) | Cutting speed F (mm/min) | Feed rate f (mm/rev) | Cutting speed F (mm/min) | Feed rate f (mm/rev) | Cutting speed F (mm/min) | Feed rate f (mm/rev) |

| 4 | 60-70-80 | 0.08-0.1-0.15 | 40-60-70 | 0.07-0.09-0.15 | 25-34-45 | 0.06-0.08-0.1 |

| 6 | 0.1-0.15-0.2 | 0.15-0.13-0.2 | 0.06-0.09-0.15 | |||

| 8 | 0.15-0.2-0.25 | 0.15-0.18-0.25 | 0.08-0.12-0.15 | |||

| 10 | 0.2-0.25-0.3 | 0.15-0.2-0.25 | 0.1-0.15-0.18 | |||

| 12 | 0.2-0.27-0.35 | 0.2-0.23-0.3 | 0.12-0.17-0.2 | |||

| 16 | 0.25-0.3-0.35 | 0.2-0.25-0.3 | 0.15-0.18-0.2 | |||

| Processing material | Gray cast iron | Ductile iron | Stainless Steel | Titanium alloy | ||||

| FC250 (250HB) | FCD450 (300HB) | SUS304、SUS316 (~200HB) | Titanium alloy | |||||

| Outer diameter D (mm) | Cutting speed F (mm/min) | Feed rate f (mm/rev) | Cutting speed F (mm/min) | Feed rate f (mm/rev) | Cutting speed F (mm/min) | Feed rate f (mm/rev) | Cutting speed F (mm/min) | Feed rate f (mm/rev) |

| 4 | 60-70-100 | 0.08-0.12-0.15 | 50-60-80 | 0.07-0.1-0.15 | 30-50-60 | 0.07-0.1-0.13 | 20-30-40 | 0.05-0.06-0.1 |

| 6 | 0.1-0.15-0.2 | 0.15-0.13-0.2 | 0.1-0.12-0.15 | 0.05-0.07-0.1 | ||||

| 8 | 0.15-0.2-0.25 | 0.15-0.18-0.25 | 0.1-0.14-0.18 | 0.06-0.09-0.12 | ||||

| 10 | 0.2-0.25-0.3 | 0.15-0.22-0.25 | 0.12-0.17-0.2 | 0.08-0.12-0.15 | ||||

| 12 | 0.2-0.28-0.35 | 0.2-0.25-0.3 | 0.15-0.2-0.23 | 0.1-0.13-0.15 | ||||

| 16 | 0.25-0.3-0.35 | 0.25-0.27-0.3 | 0.2-0.23-0.25 | 0.1-0.15-0.18 | ||||

Keywords: GS series economic efficiency drill bits

Online Message

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved