News

Product Update | CNC Drill Bit for Hardened Steel

Release time:

2025/06/09

Introduction

We are pleased to announce the launch of our newly developed CNC Drill Bit for Hardened Steel, specifically designed to handle high-hardness materials commonly used in die, mold, and automotive part production. This tool is built for superior performance in extreme conditions, where conventional drill bits often fail.

Design Overview

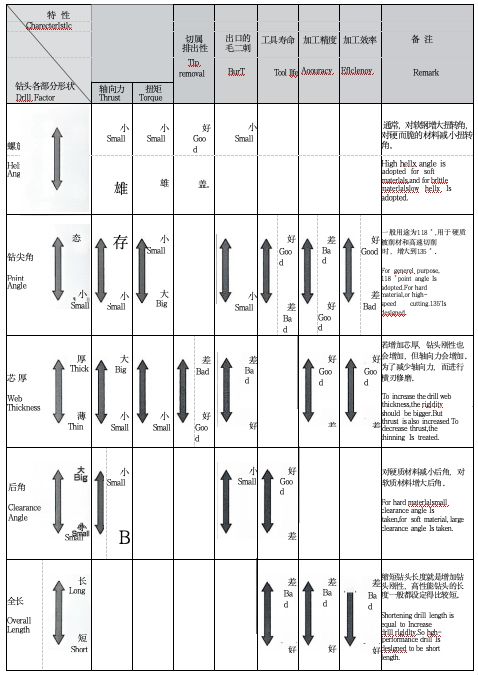

This drill bit is the result of rigorous optimization in geometry and material selection. According to the structural analysis chart (see reference image), the tool features a high-performance combination of design elements that work together to ensure stability, accuracy, and durability when drilling hardened materials (HRC 45 and above).

Key geometric parameters include:

• Helix Angle: A high helix angle improves chip evacuation and reduces heat accumulation.

• Point Angle: A small point angle enhances centering ability and minimizes walking on hard surfaces.

• Web Thickness: The web is thickened to increase structural rigidity and support higher axial loads.

• Clearance Angle: A large clearance angle reduces contact friction and helps prevent premature tool wear.

• Overall Length: A short overall length improves rigidity and reduces vibration during high-speed machining.

Each of these design choices is based on tested performance criteria and industry feedback, providing a drill bit that performs reliably in difficult environments.

Performance Characteristics

The drill bit performs exceptionally well on CNC machines, even under demanding conditions such as high-speed dry cutting or deep-hole drilling. Testing shows it maintains:

• Stable torque and low vibration

• Consistent cutting edge performance

• Longer tool life compared to conventional high-speed steel (HSS) drills

• High hole precision and surface finish

The tool’s edge profile and body design reduce the likelihood of chipping or rapid wear, which are common issues when drilling through hardened steel.

Application Scenarios

This CNC Drill Bit for Hardened Steel is well-suited for various manufacturing applications involving hardened materials, including:

• Injection mold components

• Die steel blocks and mold bases

• Automotive drivetrain parts (shafts, gears)

• Aerospace alloy components

• General tool steel machining

It is compatible with vertical and horizontal CNC machining centers, and performs well in both dry and semi-lubricated cutting conditions.

Conclusion

Machining hardened steel requires tools with exceptional strength, stability, and heat resistance. This newly released CNC Drill Bit for Hardened Steel is engineered precisely for that purpose, offering users enhanced productivity, fewer tool changes, and better drilling results.

For more technical information, trial samples, or distributor inquiries, please contact our sales team.

keywords

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved