News

Advancements in Milling Cutter Technology for Precision and Efficiency

Release time:

2025/08/11

Milling Cutter Technology Advancements in Modern Manufacturing

In the ever-evolving world of modern manufacturing, milling cutters play a crucial role in shaping, cutting, and finishing a wide variety of materials. These rotary cutting tools are essential in machining processes across industries such as automotive, aerospace, mold making, and precision engineering. Over the past decade, significant advancements in materials, coatings, and design geometry have transformed milling cutter performance, enabling manufacturers to achieve higher productivity, better surface finish, and longer tool life.

One of the most notable trends in milling cutter development is the integration of advanced carbide and high-speed steel (HSS) materials, along with the application of nanostructured coatings such as TiAlN (titanium aluminum nitride) and AlCrN (aluminum chromium nitride). These coatings not only enhance heat resistance but also reduce friction between the tool and the workpiece, allowing higher cutting speeds and feeds. As a result, machining efficiency is improved while reducing wear and extending tool life.

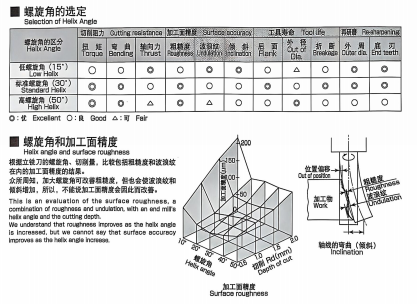

In addition to material advancements, milling cutter geometry has seen substantial innovation. Manufacturers now design cutters with variable helix angles, differential pitch teeth, and optimized flute designs to reduce vibration and chatter during machining. This results in improved dimensional accuracy and a smoother surface finish, particularly when cutting hard-to-machine materials like titanium alloys and hardened steels. Multi-flute end mills, high-feed milling cutters, and indexable insert cutters are increasingly popular, offering flexibility in both roughing and finishing operations.

CNC (Computer Numerical Control) technology has also influenced milling cutter evolution. Modern cutters are now designed to match high-speed machining strategies, allowing manufacturers to remove more material in less time without compromising quality. In industries such as aerospace, where complex 3D profiles are common, ball-nose end mills and tapered milling cutters are indispensable for precision contouring and surface finishing.

Another important development is the focus on sustainability and cost-effectiveness. Tool manufacturers are creating milling cutters that maximize material removal rate while minimizing energy consumption. Regrindable and replaceable insert designs further reduce waste and tooling costs. This shift toward eco-friendly manufacturing not only benefits the environment but also helps companies maintain competitiveness in a challenging global market.

Looking ahead, the future of milling cutter technology is expected to integrate smart manufacturing principles. Embedded sensors may soon monitor tool wear, cutting forces, and temperature in real time, enabling predictive maintenance and reducing unplanned downtime. Combined with AI-driven machining strategies, these intelligent milling tools will further optimize efficiency and product quality.

Overall, the evolution of milling cutters is a testament to the synergy between material science, mechanical engineering, and digital manufacturing. By adopting advanced milling cutter solutions, industries can achieve higher precision, faster production cycles, and greater sustainability — all of which are critical to meeting the demands of modern manufacturing.

keywords

Previous Page

Previous Page:

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved