News

Efficiency Heavy Cutting Milling Cutter Enhancing Industrial Machining Performance

Release time:

2025/10/13

Efficiency Heavy Cutting Milling Cutter Boosting Precision and Productivity in Industrial Machining

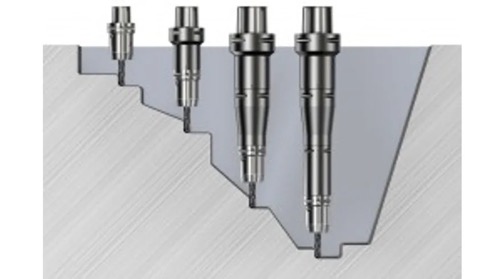

The efficiency heavy cutting milling cutter has become a pivotal tool in modern manufacturing and machining industries. With increasing demand for faster production cycles, higher material removal rates, and extended tool life, manufacturers are turning to advanced milling cutters that combine precision, durability, and efficiency. These cutting tools are designed to handle heavy-duty operations, offering significant improvements in machining performance and operational cost reduction.

Technical Overview

An efficiency heavy cutting milling cutter is engineered for high-speed, high-feed, and high-depth milling applications. Unlike standard milling tools, these cutters are optimized to remove large volumes of material in a single pass, while maintaining stability and minimizing vibrations. They feature robust geometries, multi-flute designs, and advanced coating technologies to enhance cutting efficiency and surface finish. The cutter body is typically made of high-strength steel or carbide composites, providing superior rigidity and resistance to wear during heavy cutting operations.

Advantages in Industrial Applications

-

High Material Removal Rate: An efficiency heavy cutting milling cutter can achieve significantly higher material removal rates compared to conventional cutters, reducing cycle times and improving production efficiency.

-

Improved Surface Quality: Advanced flute design and coating reduce built-up edges and friction, resulting in smoother surfaces and reduced need for secondary finishing.

-

Extended Tool Life: Specialized coatings such as TiAlN or diamond-like carbon protect the cutting edges from wear and thermal damage, extending the operational lifespan of the milling cutter.

-

Vibration Control: Heavy-duty milling often induces chatter and vibrations, which can affect dimensional accuracy. Efficiency heavy cutting milling cutters are engineered with optimized flute angles and geometries to minimize these issues, ensuring precision machining.

Applications in Manufacturing

The use of an efficiency heavy cutting milling cutter spans multiple industrial sectors, including aerospace, automotive, mold making, and die manufacturing. It is particularly beneficial for machining tough materials such as stainless steel, titanium alloys, and hardened steels. These cutters are often deployed in large-scale milling machines, CNC centers, and multi-axis machining centers, providing consistent performance even under demanding cutting conditions.

Market Trends and Growth

The global demand for high-efficiency milling tools is growing rapidly, driven by the need for shorter production cycles, automation, and high-precision machining. Industry reports indicate that advanced milling cutters, including efficiency heavy cutting milling cutters, are becoming integral components in modern smart factories, particularly in regions with high-value manufacturing like Europe, North America, and East Asia. Continuous innovations in tool geometry, coatings, and materials are expanding the capabilities of heavy-duty milling, enabling manufacturers to achieve higher productivity with lower operational costs.

Challenges and Future Outlook

While efficiency heavy cutting milling cutters provide many advantages, challenges remain in their design and application. Maintaining edge stability under extreme cutting forces, managing heat generation, and minimizing vibration in high-speed operations are ongoing engineering challenges. Research and development continue to focus on innovative geometries, hybrid materials, and advanced coatings to enhance cutting efficiency and tool longevity.

Looking forward, the integration of these cutters into automated and AI-driven machining systems will further improve production efficiency and quality. With the rise of Industry 4.0 and smart manufacturing, efficiency heavy cutting milling cutters are poised to play a critical role in the evolution of high-performance machining.

Conclusion

The efficiency heavy cutting milling cutter represents a major advancement in cutting tool technology. Its combination of high material removal rates, durability, vibration control, and surface quality improvement makes it an indispensable tool for modern manufacturing. By adopting these advanced milling cutters, industries can achieve greater productivity, reduce costs, and maintain precision, ensuring competitiveness in today’s demanding manufacturing environment.

keywords

Previous Page

Previous Page:

Latest News

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved