News

Analysising the Key Factors of Drill Bit

Release time:

2025/05/22

Deep hole drilling presents unique challenges that demand careful consideration of cutting mechanics, tool geometry, and operational parameters. Understanding the interplay between cutting edge state, thrust forces, relief shapes, and thinning geometries is essential for achieving optimal results in demanding applications.

Cutting Edge Integrity and Thrust Management

The condition of the cutting edge directly influences both machining quality and tool life. A sharp, properly honed edge reduces cutting resistance while maintaining dimensional accuracy. However, excessive edge wear leads to increased thrust forces that can cause deflection in long drill bits, resulting in hole straightness issues. Advanced coatings like AlTiN or diamond-like carbon (DCN) significantly enhance edge durability when machining difficult materials. Simultaneously, controlling cutting thrust through proper feed rate optimization prevents work hardening in materials like stainless steels and nickel alloys.

Strategic Relief and Thinning Geometries

Strategic Relief and Thinning Geometries

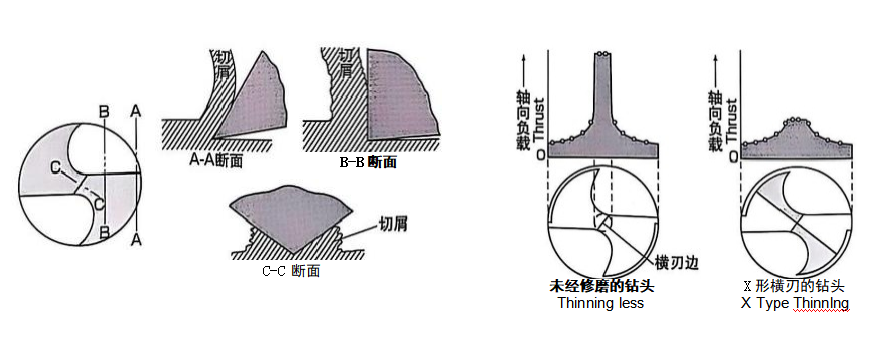

The relief angle behind the cutting edge must balance clearance requirements with structural support. Conventional 118° point angles work well for general purposes, but deep hole applications often benefit from specialized 130-140° configurations that improve chip evacuation. Thinning the web near the drill point reduces thrust forces by up to 30%, particularly important when drilling depth-to-diameter ratios exceeding 10:1. Modern parabolic flute designs combine aggressive thinning with enhanced rigidity, allowing higher metal removal rates without sacrificing hole quality.

Drill Selection Criteria and Performance Optimization

Several critical factors determine drill bit selection for deep holes:

Material-specific geometries: Cobalt alloys require positive rake angles while titanium demands reduced helix angles

Coolant delivery: Internal coolant passages should provide at least 15-20 bar pressure for effective chip removal

Stability features: Margin polishing and guided pads minimize vibration in extended reach applications

Deep Hole Drilling Best Practices

For holes deeper than 5× diameter:

Peck drilling cycles: Use 0.3-0.5×D peck increments with full retraction for chip breaking

Speed adjustments: Reduce surface speed by 20-30% compared to standard drilling parameters

Pilot holes: Essential for depths exceeding 10×D to maintain positional accuracy

Tool monitoring: Implement vibration sensors to detect early signs of tool degradation

The combination of proper tool geometry, optimized cutting parameters, and strategic process planning enables reliable deep hole drilling across aerospace, mold-making, and energy sector applications. Regular tool inspection and coolant system maintenance further ensure consistent performance in these challenging operations. By addressing both cutting mechanics and system dynamics, manufacturers can achieve superior hole quality while maximizing tool life in deep drilling scenarios.

keywords

Latest News

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved