News

CNC Carbide Twist Drill Bit for Metal – GS Series Economic Efficiency Drill Bits

Release time:

2025/06/20

The CNC carbide twist drill bit for metal has become an essential tool for precise, reliable, and cost-effective machining operations. The GS series economic efficiency drill bits are specifically designed to address the challenges of high-speed, general-purpose metal drilling while minimizing tool wear and ensuring consistent performance. With optimized geometry and robust construction, this series offers a balance of efficiency, durability, and affordability.

Engineered for Efficiency and Longevity

The GS series economic efficiency drill bit features an optimized groove shape, which enables smooth chip evacuation, reducing friction and heat during operation. This directly contributes to longer tool life and reduced maintenance downtime. A special trough design reinforces the core, allowing a larger core diameter without compromising flute space—ideal for achieving high-efficiency and long-life drilling in various metal materials.

The higher rigidity of the tool body minimizes deflection and vibration, especially under high-speed or deep drilling conditions. This is particularly critical in CNC applications where tight tolerances and surface finish are priorities.

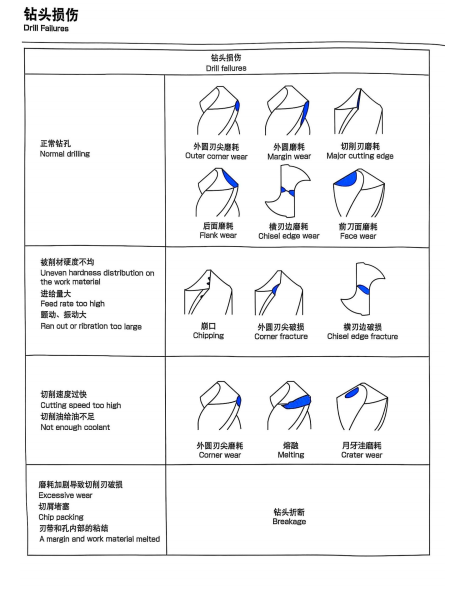

Common Drill Failures and How GS Series Reduces Them

In reference to the common drill failure types shown in the technical image, the GS series is built to help reduce wear and breakage seen in conventional drills:

• Outer corner wear, margin wear, flank wear, and chisel edge wear are common with standard drills due to inadequate chip removal and excessive heat. The GS series’ enhanced flute geometry and carbide composition mitigate these issues effectively.

• In cases of chisel edge fracture or corner fracture, often caused by excessive feed or vibration, the rigid design of the GS series ensures higher resistance to mechanical stress.

• Issues like melting or crater wear, typically caused by improper cooling or excessive cutting speed, are less likely when GS series bits are used under recommended cutting conditions.

• For operations prone to breakage, especially in hard metals or unstable setups, the strong carbide base and optimized core structure significantly improve reliability and reduce tool failure rates.

Best Practices for Optimal Use

To maximize the performance and lifespan of CNC carbide twist drill bits for metal, users should:

• Ensure proper alignment and machine rigidity to avoid runout and vibration.

• Use appropriate cutting fluid and ensure it reaches the tool tip during deep hole drilling.

• Follow recommended speed and feed rates based on material type and drill size.

• Periodically inspect tools for early signs of wear to avoid catastrophic failure.

Versatile Applications Across Metalworking Industries

The GS series is suitable for machining a wide range of ferrous and non-ferrous metals, including carbon steels, stainless steels, and aluminum alloys. Whether in the automotive, aerospace, or manufacturing sector, the economic efficiency drill bits provide a reliable solution for high-precision and cost-effective metal drilling tasks.

Technical Advisory & Product Support

Please note that technical parameters are provided for reference only. Actual tool performance will vary depending on machining environment, material hardness, and setup quality. Users are advised to consult technical support when uncertain about cutting conditions, unusual tool wear, or system compatibility.

The GS series economic efficiency drill bits represent a new standard in affordable carbide drilling tools, delivering robust results in CNC machining of metal components. For more information, consult the Product Center or reach out to our technical team for personalized assistance.

keywords

Previous Page

Previous Page:

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved