News

WX Series 750 Round Nose Knife Efficient Solution Designed for Materials Above HRC55

Release time:

2025/07/18

WX Series 750 Round Nose Knife Offers Precision and Durability for High-Hardness Mold Processing

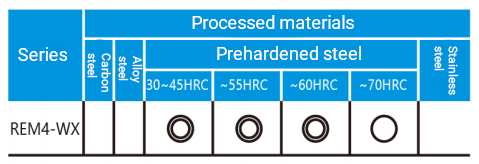

In the rapidly evolving world of mold manufacturing, where tool precision, wear resistance, and longevity are paramount, manufacturers are constantly seeking innovative solutions to meet the growing demands of high-hardness material processing. The WX Series 750 round nose knife from China has emerged as a cutting-edge solution for professionals looking to enhance productivity and tool life when working with hardened materials rated HRC55° to 75°. Built with precision engineering and high-performance materials, this round nose end mill sets a new benchmark in mold machining technology.

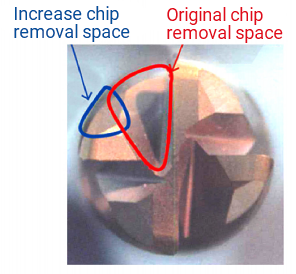

The WX Series 750 high-hardness round nose knife incorporates HD multi-layer hard coatings, specifically designed to withstand the extreme heat and abrasion generated during high-speed, high-precision cutting. These coatings include heat-resistant, wear-resistant, and hard-layer components that synergize to offer exceptional durability. This technological advancement significantly extends the tool's lifespan, allowing for longer machining cycles and fewer tool changes, thus optimizing the overall manufacturing process.

At the core of this round nose knife is an ultra-fine grain carbide rod made from 0.3μm submicron cemented carbide. This material choice is not arbitrary — it delivers unmatched hardness, edge retention, and toughness, all essential for maintaining cutting performance under rigorous machining conditions. This makes the WX Series 750 an ideal tool for operations requiring high-speed machining of hardened steels commonly used in mold and die industries.

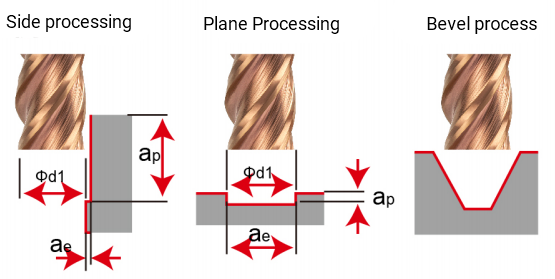

What sets this tool apart is not just its materials or coatings, but the meticulous engineering behind its round nose geometry. This shape is especially beneficial for 3D profiling, cavity cutting, and surface contouring in die and mold applications. The round tip provides superior strength at the cutting edge, reducing the likelihood of chipping and breakage when compared to flat-end mills, especially when engaging in deep pocketing or complex curved surface finishing.

The WX Series 750 round nose knife offers a comprehensive solution for global manufacturers seeking a reliable and efficient cutting tool for mold processing. Its application extends across industries such as automotive, aerospace, electronics, and industrial equipment manufacturing — sectors where precision molds and dies play a critical role in final product performance.

From a cost-efficiency standpoint, the extended tool life reduces downtime and maintenance costs. Operators benefit from increased output with less machine wear, reinforcing the economic value of choosing a high-performance round nose knife. When coupled with automated or CNC-controlled equipment, the WX Series 750 seamlessly integrates into modern manufacturing environments.

This premium round nose knife from China addresses the limitations of conventional tools when applied to high-hardness material. It enables smoother machining operations, minimal surface defects, and greater dimensional accuracy, ultimately resulting in better-finished parts and fewer quality issues downstream. For companies aiming to scale up their production capacity while maintaining tight tolerances and surface quality, this tool is an indispensable asset.

Moreover, the tool’s excellent thermal stability ensures consistent performance even during long and intensive cutting sessions. This is especially vital in operations involving hardened tool steels, which are notoriously difficult to machine. The multi-layer coating system not only prevents heat buildup but also resists oxidation and chemical degradation, giving users the confidence to push cutting parameters further.

As global competition in manufacturing continues to rise, companies must prioritize investment in tooling that ensures reliability, precision, and cost-effectiveness. The WX Series 750 round nose knife is more than just a cutting tool — it's a productivity enhancer and a technological ally in the push toward smart, efficient, and sustainable manufacturing.

In summary, whether you are a tool shop looking to boost your mold-making capabilities or an industrial manufacturer striving for higher machining precision, the WX Series 750 high-hardness round nose knife delivers a compelling value proposition. With superior material composition, advanced coating technology, and purpose-driven geometry, this Chinese-made tool stands out as one of the top-tier solutions in today’s tooling landscape.

keywords

Previous Page

Previous Page:

Latest News

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved