News

Precision-Driven CNC Drill Bit for Mold Making Applications – GS Series Economic Efficiency Drill Bits

Release time:

2025/06/23

For manufacturers and toolmakers seeking a dependable solution in precision mold processing, the CNC drill bit for mold making applications must combine durability, chip control, and high-efficiency drilling. The GS series economic efficiency drill bits are engineered to meet these stringent requirements by offering a specialized geometry that ensures stable performance in both soft and hardened mold steels.

Built for Mold Machining Precision

The GS series economic efficiency drill bit features an optimized groove shape designed to improve chip evacuation, reduce friction, and prevent heat buildup during continuous drilling cycles. This is especially important in mold-making environments where the materials being processed—such as H13, SKD11, or P20—are typically dense and abrasive.

The drill’s special trough design increases the core diameter under the same flute spacing, greatly enhancing its structural integrity. The result is a stronger tool that resists deflection, even under high axial loads or deep-hole drilling conditions, making it ideal for mold making applications where dimensional precision is paramount.

Superior Chip Control Reduces Downtime

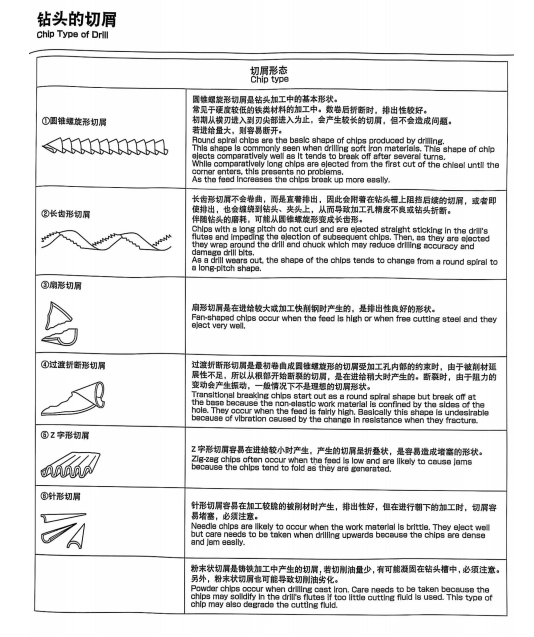

One of the major challenges in mold drilling is chip evacuation. According to the illustrated chip types, improper chip control can lead to heat accumulation, tool wear, and even tool breakage. The GS series addresses this by promoting a clean and consistent chip flow.

For instance:

• It helps avoid the formation of fan-shaped chips and Z-shaped twisted chips, both of which are prone to jamming and can interrupt continuous drilling.

• With the right parameters, the GS series produces spiral or short spiral chips, which are easier to evacuate and indicate stable cutting.

• By minimizing the risk of arc chips or powder chips—often signs of poor lubrication or unsuitable feed/speed combinations—the tool ensures consistent performance and reduces the need for frequent tool changes or machine stoppages.

Enhanced Rigidity for Deep Hole Drilling

In mold applications, precision cavities often require deep hole drilling. The GS drill bit’s enhanced rigidity ensures minimal vibration and tool deflection, even at greater depths. This means tighter tolerances and better alignment in high-value mold cores or inserts.

Moreover, the combination of rigidity and chip removal performance ensures the tool can operate with reduced wear over extended cycles, lowering cost-per-hole and increasing overall productivity.

Technical Guidance for Best Results

To achieve optimal outcomes when using CNC drill bits for mold making applications, users should adhere to the following guidelines:

• Maintain proper feed and speed to promote ideal chip shapes like spirals.

• Ensure sufficient coolant supply, especially during deep drilling, to avoid the formation of powder or melted chips.

• Regularly inspect the tool’s wear surfaces to identify early signs of failure (e.g., chisel edge wear or corner fractures).

• Avoid excessive cutting force which could lead to chipping or spiral distortion.

Reliable Performance Across Mold Materials

Whether you’re machining pre-hardened steels, tool steels, or softer aluminum mold blocks, the GS series economic efficiency drill bits provide consistent results. Their versatility makes them suitable for cavity drilling, ejector pin holes, cooling channel bores, and other common mold-processing tasks.

By reducing tool change frequency, improving hole quality, and ensuring predictable chip behavior, the GS series sets a new benchmark for high-efficiency mold drilling.

Important Notice

All parameters provided are for reference only. Actual results depend on specific material characteristics, setup stability, lubrication method, and operator control. For special conditions or abnormal tool wear, please consult our technical service team for support.

The CNC drill bit for mold making applications—represented by the GS series—is your reliable partner in precision mold manufacturing, bringing together economic efficiency and cutting-edge engineering in one durable solution.

keywords

Previous Page

Previous Page:

Latest News

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved