News

Advantages of titanium alloy milling cutter

Release time:

2022/11/29

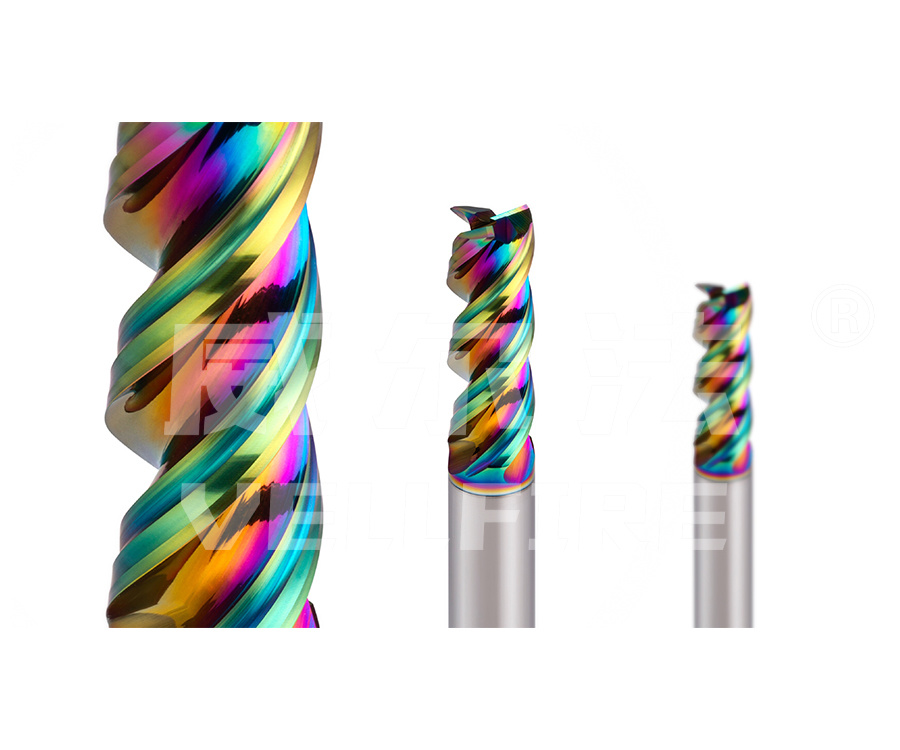

As a new type of alloy material, titanium alloy has great advantages in new energy, which can not be compared with other metals. Although the price is more expensive, it is widely used in many fields because of its characteristics. So, let's take a look at the following.titanium alloy milling cutterThe advantages.

titanium alloy milling cutter advantages:

1. High strength

The density of titanium alloy milling cutters is typically about 4.51g/cm3. Only 60% of steel. The strength of some high-strength titanium alloy milling cutters exceeds the strength of many alloy structural steels. Therefore, the specific strength (strength/density) of is high compared to other metal structural materials, and parts having high unit strength, good rigidity, and light weight can be produced.

2. High thermal strength

Can work continuously at 450500 temperatures. Both titanium alloys are still high in the 150500 range. Specific strength, the specific strength of magnesium aluminum alloy decreased significantly under 150. The use temperature of titanium alloy can reach 500. The use temperature of magnesium aluminum alloy can be lower than 200.

3. Good corrosion resistance

titanium alloy milling cutterWorking in twisted seawater, its corrosion resistance is far better than stainless steel. Especially against pitting corrosion, acid corrosion, stress corrosion of alkali, chloride, chlorine containing organic matter, nitric acid, sulfuric acid resistance.

4. Good low temperature performance

Titanium alloy milling cutters can maintain mechanical properties at low and extremely low temperatures. Titanium alloys with good low temperature properties and very low interstitial elements (such as TA7) can maintain a plasticity of about-253C. Therefore, titanium alloy is also an important low-temperature structural material.

5. High chemical activity

Titanium has high chemical activity, in the atmosphere with O2, N2, H2, CO, CO2, water vapor, ammonia and other strong chemical reaction. If the carbon content exceeds 0.2%, titanium absorbs oxygen and forms a high hardness solidified layer when the temperature rises 600 in the titanium alloy milling cutter; the hydrogen content increases; when the temperature rises, when it interacts with n, a hard surface layer of TiN is also formed. An embrittlement layer is also formed. Under the action of absorbed gas, the hard and brittle surface depth reaches 0.10.15mm, and the hardening degree is 20% 30%. Titanium has a high chemical affinity and can reach the friction surface.

6. Low resonance coefficient

The thermal conductivity of titanium = 15.24w/(m) is about 1/4 of nickel, 1/5 of iron and 1/14 of aluminum. The rate is about 50.% lower. The elastic modulus of titanium alloy milling cutter is about 23 stainless steel.

The above introduction istitanium alloy milling cutterThe advantages. If you need to know more, you can contact us at any time! Our company has many years of experience and looks forward to your joining at any time.

keywords

Latest News

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved