News

Design and Characteristics of Titanium Alloy Milling Cutter

Release time:

2022/12/20

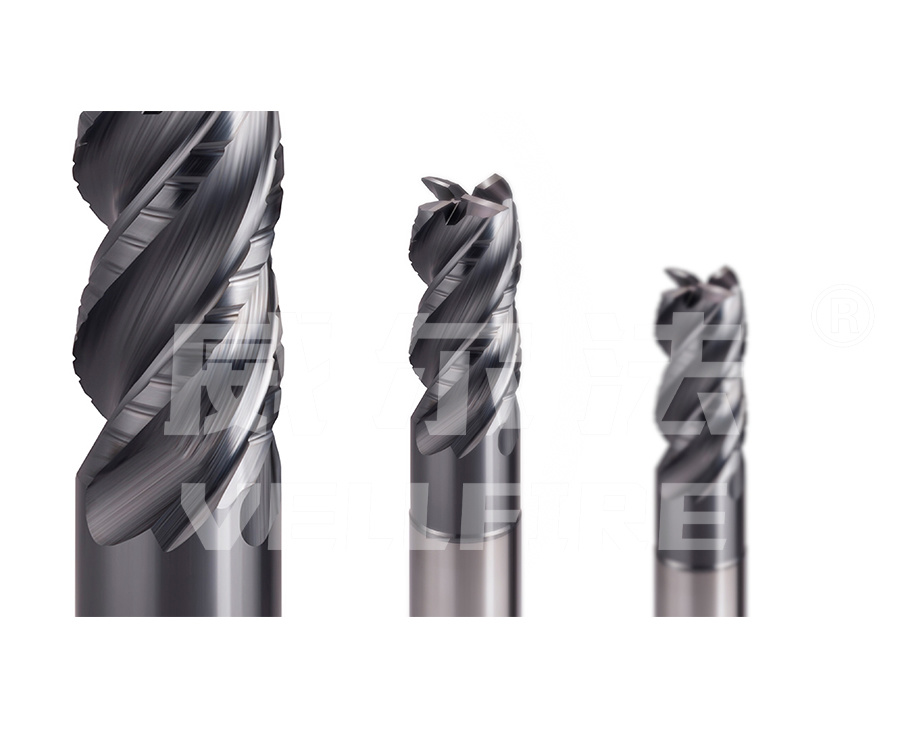

titanium alloy milling cutterIt has the characteristics of high strength, high temperature resistance, good wear resistance, and good comprehensive mechanical properties. It has a wide range of applications, but at the same time it has the characteristics of low thermal conductivity, small elastic modulus, high specific strength, and good corrosion resistance. It is a difficult processing material. High speed cutting with low cutting force, high machining efficiency, high machining accuracy and durability, is widely used in manufacturing industry. However, due to its difficult processing characteristics, the actual processing efficiency and tool durability is low, which has become one of the bottlenecks restricting the development of the manufacturing industry. So, let's take a look at the design and characteristics of titanium alloy milling cutters.

Many foreign scholars have studied the cutting characteristics of titanium alloys. After a large number of experiments, titanium alloy milling cutter was found to cut 628m/minHartungP m with titanium alloy milling cutter. D. et al. believed that the cutting speed of continuous high-speed cutting of titanium alloy should not exceed 200 m/min. The wear mechanism of titanium alloy milling cutter was deeply studied. When WC-Co-based cemented carbide and PCD were applied, the carbon in the cutter reacted with titanium alloy chips at the interface.

Domestic aviation, aerospace and military industries have carried out the research and application of titanium alloy milling cutter, parts mainly structural parts, mainly to solve the problem of processing efficiency and tool durability.

High-speed steel tools are generally used for the processing of titanium alloys, but if the cutting speed exceeds 30 m/min and the cutting speed of carbide tools exceeds 60 m/min, the processing process will become difficult. In the cutting process of titanium alloy milling cutter, when the cutting speed reaches more than 100 m/min, it enters the high-speed cutting range. At present, the cutting speed of foreign milling is generally in the range of 100-200 m/min, and the application of high-speed cutting is high.

titanium alloy milling cutterDesign:

1. Structural design

Development of groove type: titanium alloy milling cutter before and after optimization of the groove type. When cutting titanium alloy, in the third deformation area, the interface wear between the tool and the workpiece is more serious, and the titanium alloy is higher than the strength, so the chip and cutting force in the cutting process also need to be controlled. In view of this situation, the forming grinding technology is used to optimize the groove design, taking into account the large chip space, chip removal space, tool stiffness and sharp tool rake angle.

If the core thickness of the tool is unchanged, that is, the rigidity is unchanged, the groove bottom of the tool becomes quite wide, the chip space becomes larger, the chip removal resistance becomes smaller, and the tool wear becomes slower. At the same time, in order to reduce the vibration in the cutting process and improve the cutting efficiency, the five-edge structure is determined through theoretical analysis and experimental optimization.

In order to reduce the cutting vibration, the unequal spacing design is adopted. In order to further control the vibration, the tool peripheral edge adopts a double-blade design rake face, along the spiral groove cutting eccentric angle, to ensure the dynamic balance of the tool during high-speed milling. (a) Unequal tooth structure: B) Double cutter mill back edge surface

titanium alloy milling cutterFeatures:

1. Selection of substrate

The grain size of WC in ultrafine grained cemented carbide is small, generally 0.2-0.5m. It has the characteristics of high hardness, high strength and high wear resistance. Its hardness is generally 90-93HRA, and its bending strength is 2000-4000MPa. It is not easy to interact with the processed material.

Four kinds of hard alloy base metal varieties were selected, namely a-K30F, b-K40F, c-K44F and d-K88F. Tool diameter specification D20mm, cutting parameters: cutting speed Vc = 100 m/min, feed per revolution f = 0.2mm/r, cutting depth ap = 10mm, cutting width AE = 1mm. Tool wear after cutting 160min.

The above introduction is the design and characteristics of titanium alloy milling cutter. If you need to know more, you can contact us at any time! Our company has many years of experience and looks forward to your joining at any time.

keywords

Latest News

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved