News

High Hardness End Mill Enhance Precision and Efficiency in Modern Machining

Release time:

2025/10/20

In the world of precision machining, the high hardness end mill has become a critical tool for achieving superior performance, efficiency, and longevity. Designed to handle tough materials and high-speed operations, high hardness end mills are essential for industries ranging from aerospace and automotive to mold making and general metalworking. Their unique combination of material composition, geometry, and surface treatment allows them to maintain sharp cutting edges under extreme conditions, providing precise cuts and consistent quality throughout the machining process.

One of the most significant highlights of high hardness end mills is their exceptional material strength. Typically made from solid carbide or high-speed steel with advanced coatings, these tools can withstand high temperatures and cutting forces without deforming or losing their sharpness. Solid carbide end mills, in particular, offer superior rigidity, enabling high-speed machining with minimal vibration, which translates into smoother surface finishes and extended tool life. Coatings such as TiAlN (titanium aluminum nitride) or DLC (diamond-like carbon) further enhance hardness, reduce friction, and protect the tool from wear, oxidation, and thermal damage.

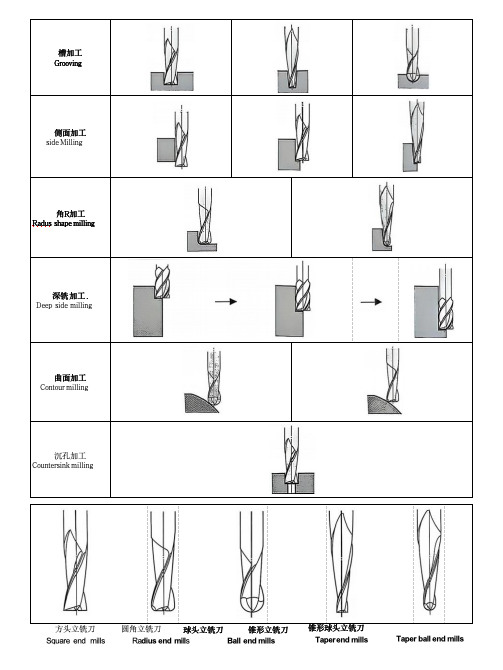

High hardness end mills are designed with optimized geometries to improve cutting efficiency. Helix angles, flute designs, and corner radii are carefully engineered to reduce cutting resistance, evacuate chips efficiently, and maintain surface quality. Variable helix designs, for instance, minimize chatter and vibration during milling, ensuring higher precision and better surface finishes. The choice between flat, ball, or corner-radius end mills allows machinists to select the optimal tool for specific applications, whether roughing, finishing, or profiling complex 3D surfaces.

Another technological advantage is the ability to machine hard-to-cut materials. High hardness end mills excel in processing stainless steel, titanium alloys, hardened steels, and exotic superalloys, which are commonly used in high-performance components. Their superior hardness and toughness allow for high material removal rates while maintaining tight tolerances and excellent dimensional accuracy. This capability is critical in industries where both precision and production efficiency are paramount, such as aerospace engine components, medical implants, and high-performance automotive parts.

Durability and cost-effectiveness are additional benefits of high hardness end mills. By maintaining sharpness longer and resisting wear, these tools reduce the frequency of replacements and downtime in production lines. Advanced manufacturing techniques, such as precision grinding and cryogenic treatment, further enhance tool life by relieving residual stresses and improving toughness. As a result, manufacturers can achieve higher throughput, lower scrap rates, and better overall productivity.

High hardness end mills also offer versatility in various machining strategies. They are compatible with dry machining, high-speed cutting, and CNC milling operations. With proper tool selection and cutting parameters, machinists can optimize speed, feed, and depth of cut to achieve maximum efficiency and surface quality. The combination of high hardness, thermal stability, and advanced geometries ensures that these tools can meet the demands of modern precision manufacturing, from single-part prototypes to large-scale production runs.

In addition to technical performance, high hardness end mills contribute to process reliability and safety. Reduced vibration, improved chip evacuation, and lower cutting forces decrease the likelihood of tool breakage and machine stress, creating a safer working environment. Advanced coatings also minimize heat generation, reducing thermal deformation of both the workpiece and the tool, which is especially critical when working with heat-sensitive or high-strength materials.

In conclusion, high hardness end mills are indispensable tools in modern machining, combining advanced material properties, precise geometries, and innovative coatings to deliver superior performance. Their ability to handle tough materials, maintain sharpness under extreme conditions, improve efficiency, and ensure process reliability makes them essential for industries demanding precision and productivity. As manufacturing technology continues to evolve, high hardness end mills will remain a cornerstone of advanced machining solutions, driving innovation, quality, and efficiency across multiple sectors.

keywords

Previous Page

Latest News

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved