News

Enhancing CNC Micro Carbide End Mill for Fine Detail Milling Performance Through Optimal Milling Practices

Release time:

2025/10/17

Optimizing Milling Techniques for Longer Tool Life

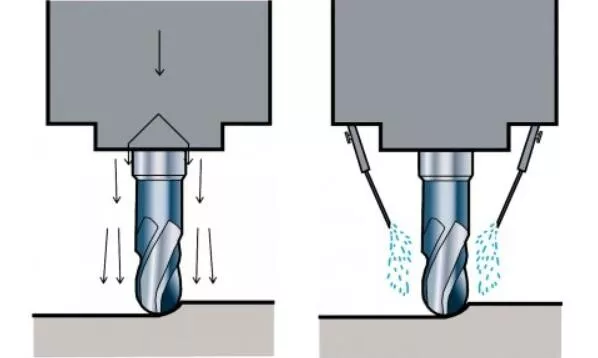

The milling process is inherently an intermittent cutting operation, which causes the temperature at the cutting edge to fluctuate between high and low extremes, often reaching around 1000 ℃. Such temperature variations can significantly impact the performance and lifespan of the tool, especially when using CNC micro carbide end mill for fine detail milling. One of the key factors influencing tool longevity is the use of cutting fluids, which can either mitigate or exacerbate thermal and mechanical stresses depending on the milling conditions. During cutting, the entry and exit of the tool cause abrupt temperature changes, leading to thermal shocks and cyclic stress at the cutting edge. These stresses may result in micro-cracks and, in severe cases, premature tool failure. High cutting area temperatures are generally less suitable for cutting fluid application, as the rapid thermal fluctuations may compromise the fluid’s cooling efficiency. However, in finishing operations, the heat generated is lower, and cutting fluids do not reduce tool life to the same extent as in roughing operations.

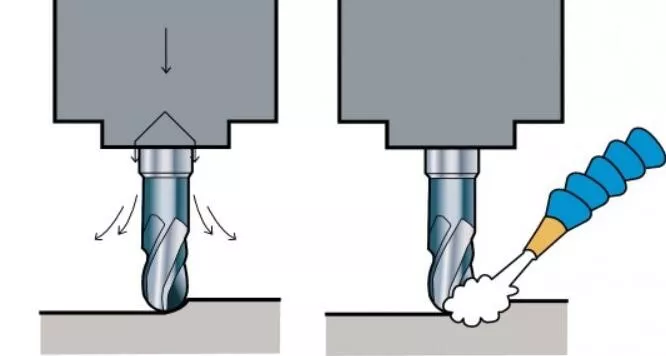

Dry milling, on the other hand, can extend the lifespan of a CNC micro carbide end mill for fine detail milling. Despite temperature variations, the heat remains within the designed tolerance of carbide materials. Rough milling operations should always be performed without cutting fluids to prevent thermal shock and to maintain tool integrity. Dry milling reduces the risk of adhesion of metal particles to the cutting edge and avoids potential chemical reactions that may occur with cutting fluids at high temperatures.

There are, however, specific situations where the use of cutting fluids is beneficial and sometimes necessary. In precision finishing of stainless steel and aluminum alloys, cutting fluids prevent metal particles from sticking to the workpiece surface, ensuring superior surface quality. For high-temperature alloys milled at low cutting speeds, fluids provide both lubrication and cooling to protect the workpiece and tool. Milling cast iron requires fluids to wash away dust and chips, maintaining a clean working environment and accurate dimensions. When working with thin-walled components, cutting fluids can help prevent geometric deformation caused by thermal expansion. Additionally, for deep cavity milling, micro-lubrication systems can be used, delivering small amounts of specialized oil with compressed air to facilitate chip evacuation. The quantity of oil in such systems is minimal, often only a few milliliters per hour, and it can be safely expelled through standard filtered ventilation.

In cases where wet milling is unavoidable, it is crucial to use sufficient amounts of cutting fluid, either through high-volume internal cooling or external cooling methods. Proper fluid application ensures effective heat dissipation, prevents chip welding, and maintains surface quality, which is particularly important when employing a CNC micro carbide end mill for fine detail milling. By understanding when to employ dry versus wet milling, and how to utilize micro-lubrication or full cutting fluids appropriately, manufacturers can significantly improve tool life, achieve precise surface finishes, and enhance overall production efficiency. Integrating these best practices ensures that carbide end mills continue to perform reliably under the demanding conditions of modern precision milling, making them indispensable tools for fine detail applications in industries ranging from aerospace to medical device manufacturing.

keywords

Latest News

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved