News

What You Must Know About Milling Cutter Types and Their Applications

Release time:

2025/06/27

Innovations in Milling Cutter Technology Drive Precision and Efficiency in Modern Manufacturing

In today’s fast-paced and competitive manufacturing environment, the demand for high-performance tools that deliver precision, versatility, and long service life is greater than ever. Among these tools, the milling cutter—particularly the end mill—plays a crucial role in various machining operations such as grooving, side milling, contour milling, and shoulder milling. With continuous advancements in materials science, geometry optimization, and surface treatment, modern milling cutters are evolving to meet the increasing complexity and tolerance requirements in industries ranging from aerospace to mold making.

Types and Functional Characteristics of Milling Cutters

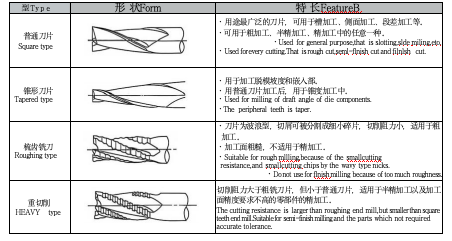

The design and form of a milling cutter directly impact its performance. For instance, square end mills are highly versatile and suitable for general applications including slotting, side milling, and step cutting. Tapered end mills are ideal for creating draft angles in die components, while roughing end mills—with their wavy cutting edges—are optimized for high material removal in rough machining stages. Ball end mills and corner radius end mills, on the other hand, are favored for contour milling of complex 3D shapes and die components requiring a smooth radius finish.

Each type of milling cutter tooth form—whether square, ball, or radius—brings distinct advantages. Square type cutters with center cutting capabilities allow for plunge cutting, which is especially beneficial in mold cavity processing. Ball end mills, although less sharp at the center, offer excellent performance for 3D profiling and copy milling, making them indispensable in precision tooling.

The Science Behind Cutter Selection

Selecting the appropriate milling cutter involves balancing factors such as the number of flutes, helix angle, and flute geometry. For example, 2-flute end mills offer superior chip evacuation, making them ideal for grooving and soft materials like aluminum. In contrast, 4-flute cutters provide better surface finishes and tool rigidity, making them suitable for harder materials and finish machining.

The helix angle also influences performance. A standard 30° helix balances cutting efficiency and surface finish, while higher helix angles improve chip evacuation and reduce cutting resistance but may increase tool deflection. As cutting speed and feed rate affect tool wear and surface quality, engineers must fine-tune these parameters to achieve optimal tool life and machining accuracy.

Tool Wear and Maintenance

Tool wear is inevitable during cutting processes. Normal wear manifests as flank wear, crater wear, and edge rounding, which can be managed through proper regrinding schedules. However, abnormal wear—such as chipping, breakage, and thermal cracks—requires immediate intervention. Key causes include excessive vibration, poor fixturing, worn cutting edges, and improper coolant application. Thus, maintaining cutting oil quality, ensuring stable fixturing, and monitoring feed rates are vital for extending cutter life.

Application-Centric Cutter Innovation

New-generation milling cutters now incorporate advanced coatings and micro geometries to minimize friction and enhance wear resistance. Multi-flute designs tailored for high-speed machining (HSM) improve productivity without compromising surface quality. Additionally, custom cutters with specific helix angles and edge preparations are now widely used to match material-specific machining requirements.

In sum, the milling cutter has evolved from a simple cutting tool to a sophisticated, application-driven solution. Its selection and optimization are critical to the success of any machining operation. As industries continue to demand higher precision, tighter tolerances, and faster production cycles, manufacturers must embrace cutter innovation not just as a cost-saving tool, but as a strategic enabler of quality and efficiency.

keywords

Previous Page

Previous Page:

Latest News

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved