News

Enhanced Precision CNC Drill Bit Offers Superior Chip Evacuation and Rigidity for High-Performance Machining

Release time:

2025/07/22

Precision CNC Drill Bit Redefining Efficiency and Longevity in Modern Machining

In the constantly evolving world of precision manufacturing, the role of cutting tools has become more critical than ever. Among these tools, the precision CNC drill bit stands as a cornerstone of modern machining—delivering accurate, efficient, and repeatable drilling operations across diverse industries. Today, a newly optimized version of the CNC drill bit is turning heads with its breakthrough design and exceptional performance, offering a substantial leap forward in chip evacuation, rigidity, and overall drilling longevity.

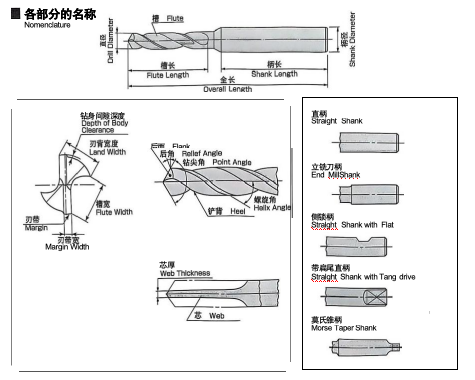

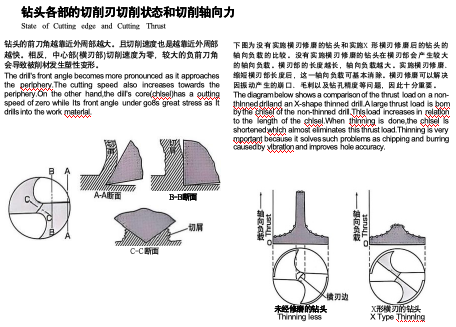

At the heart of this advanced CNC drill bit lies a specially engineered flute design. The geometry of the flute has been meticulously optimized to enhance chip evacuation—a critical factor in deep and high-speed drilling applications. Traditional drill bits often suffer from chip congestion, leading to increased friction, heat buildup, and premature tool failure. The new flute design, however, dramatically reduces these issues by providing a wider and more efficient chip path, ensuring smooth, continuous material removal even under intense operating conditions.

Moreover, the drill bit features a larger web thickness at the same flute space, effectively increasing its core diameter. This clever engineering choice results in significantly improved rigidity—a crucial attribute when maintaining dimensional accuracy during high-speed operations. The increased core strength minimizes deflection and vibration, allowing manufacturers to maintain tighter tolerances while also extending the usable life of the drill bit itself.

The implications of this design are far-reaching, particularly for industries that demand high-performance drilling—such as aerospace, automotive, electronics, and precision mold manufacturing. In such fields, even a slight increase in tool longevity or chip removal efficiency can translate into major cost savings and productivity gains over time. The precision CNC drill bit answers this call with flying colors, offering unmatched durability and machining stability even when working with tough materials like titanium alloys, hardened steels, or composite substrates.

Beyond its mechanical enhancements, this drill bit also benefits from cutting-edge coating technologies that reduce friction and increase wear resistance. The synergy between physical structure and surface treatment ensures that the bit not only lasts longer but also maintains peak performance over a greater number of cycles. For manufacturers looking to reduce tool changes, minimize downtime, and boost throughput, the precision CNC drill bit offers an optimal solution.

As digital manufacturing and automation continue to advance, the demand for reliable and intelligent cutting tools is set to rise. The latest iteration of the precision CNC drill bit exemplifies how even subtle design changes can lead to significant performance improvements. Through innovation in flute geometry, core strength, and material science, this tool has redefined expectations in CNC drilling—delivering unmatched accuracy, productivity, and value for machinists worldwide.

Ultimately, the introduction of this high-performance drill bit is more than just a product launch—it’s a clear signal of where precision manufacturing is headed. It underscores the importance of continuous innovation in even the most familiar tools and highlights how small advancements can lead to big gains in competitive advantage.

keywords

Previous Page

Previous Page:

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved