News

High performance drill bit enhances precision and durability in industrial machining

Release time:

2025/07/25

High Performance Drill Bit Revolutionizing Precision Drilling for Industrial Applications

Drill bits are fundamental tools in numerous industrial sectors, including aerospace, automotive, construction, and electronics. In recent years, high performance drill bits have redefined industry expectations by combining durability, speed, and precision. Designed to handle demanding materials and complex applications, these advanced tools are essential for maximizing productivity and maintaining consistent results in high-volume environments.

A key feature of high performance drill bits lies in the superior materials used in their construction. Many are made with ultra-fine grain tungsten carbide, a compound known for its hardness, heat resistance, and wear tolerance. This makes them exceptionally durable under high-speed machining conditions and capable of maintaining cutting efficiency over prolonged periods. With the addition of advanced coatings such as TiAIN (Titanium Aluminum Nitride) or TiCN (Titanium Carbonitride), the drill bits gain added resistance to oxidation, thermal damage, and friction—factors that commonly degrade lesser tools.

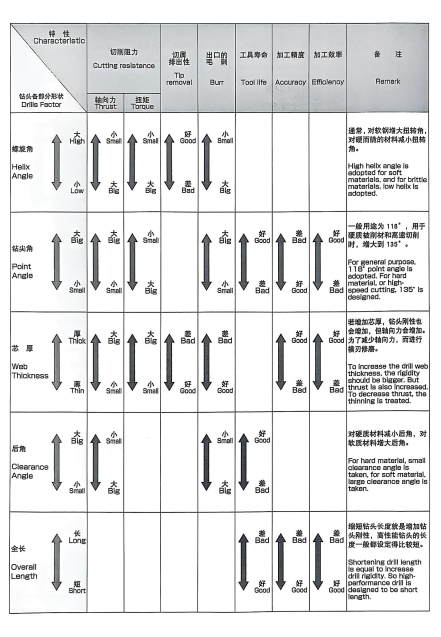

Geometry plays a vital role in performance. The latest high performance drill bits often incorporate polished flutes and reinforced cores to ensure strong chip evacuation and tool stability. Their unique cutting edge geometry reduces cutting forces and vibration while improving hole roundness and surface finish. Many also feature a split point design and a 135° point angle, which help prevent walking at the start of drilling and improve accuracy. This is particularly useful in materials like stainless steel, titanium alloys, and high-carbon steels.

These drill bits are built for versatility. Whether used in CNC machining centers, automated production lines, or handheld power tools, they deliver repeatable performance and are compatible with a wide range of materials. Common applications include automotive engine components, aerospace parts, precision molds, electronic casings, and even medical devices. In high-demand environments, they help manufacturers reduce downtime and tool replacement frequency, thereby increasing operational efficiency.

While high performance drill bits may have a higher initial cost, their long-term value is undeniable. Fewer tool changes, less scrap material, better surface finishes, and shorter cycle times contribute to lower overall production costs. Their ability to retain sharpness and structural integrity under extreme conditions makes them a smart investment for any industry focused on precision and reliability.

In summary, high performance drill bits are more than just upgraded cutting tools—they are essential components in modern manufacturing. With optimized material composition, cutting-edge geometries, and long-lasting coatings, they support the increasing demand for speed, accuracy, and quality in industrial drilling applications.

keywords

Previous Page

Latest News

Contact Information

Tel: +86-18861298766

E-mail: jeni@vellfire-tools.com

Whatsapp:8618861298766

Address: No. 156, Nanxi Road, Xinbei District, Changzhou City (Wilfa Recutting Milling Cutter and High Efficiency Drill Wholesale)

Copyright© 2023 Jiangsu Vellfire Precision Alloy Co., Ltd. All Rights Reserved